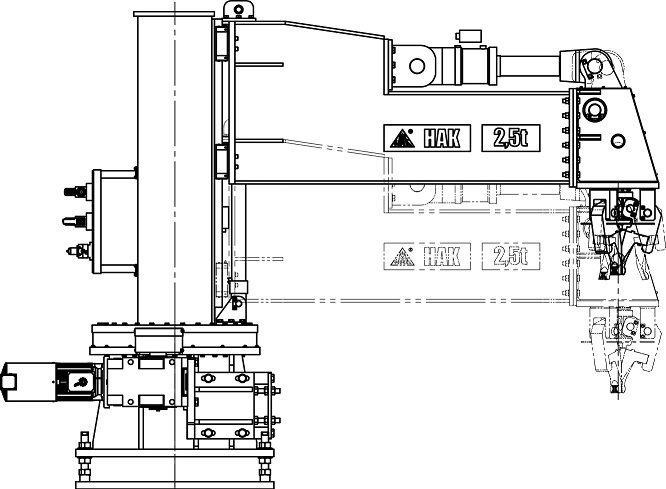

Pin-Type Manipulator Crane for Forgings

A fully automated stationary crane mounted to the floor. The device is designed for handling the production and processing of steel elements. The manipulator's construction allows for guiding the load along a path with a variable trajectory. The rotation and operation of the jaws are performed fully safely, thanks to the implemented hydraulic mechanisms. This crane can be used in extreme conditions, as it is adapted for high temperatures and challenging environments (e.g., high dust levels).

Application:

- Picking up and transporting steel elements in the form of rings between successive stages of production and processing.

Technical description:

- The manipulator crane's arm (jib) is adjustable in length and height.

- Smooth adjustment of the crane’s working speed.

- The manipulator crane is equipped with movable jaws, allowing for gripping the load from the inside.

- The crane is adapted to work in high temperatures and high-dust environments.

- Hydraulic mechanisms for adjusting height, arm extension, rotation angle, and jaw operation.

- Automatic control or control via a panel in the control cabin.

- The provided parameters can be adjusted to meet the user’s specific needs.