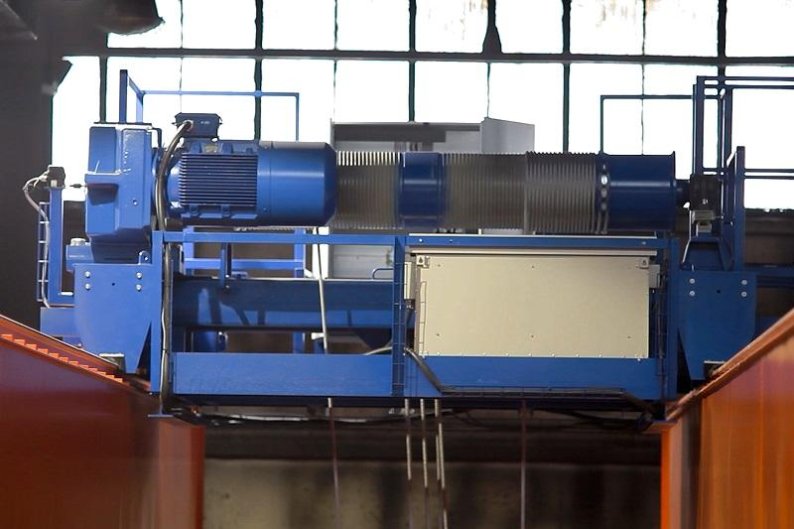

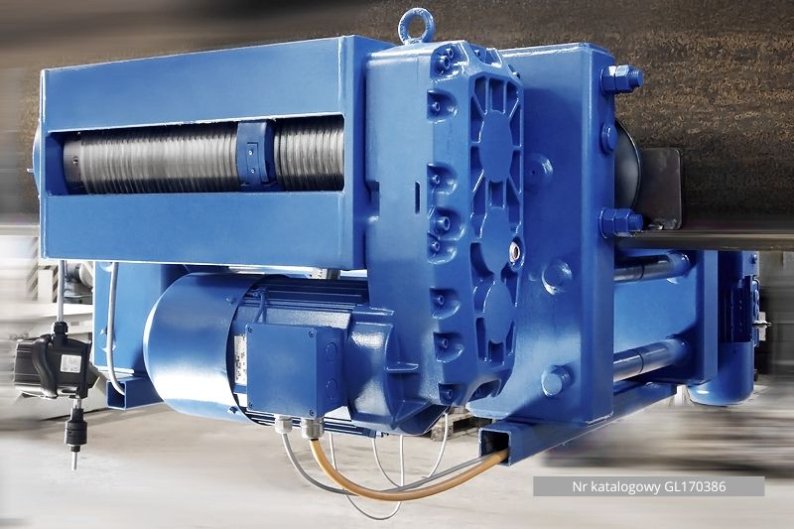

Winch with Multi-Layer Rope Guidance System TOWER

The multi-layer winch manufactured by HAK Company is equipped with an innovative multi-layer rope guidance system, in which the rope guide remains stationary, while the rope drum is mounted to move along its axis of rotation.

This solution, allowing for multi-layer winding of the rope onto the drum, significantly shortens the drum’s length and, as a result, reduces the weight of the hoist, thus minimizing the space required for its installation. The winch can also be equipped with an electronic system that detects the weight of the lifted load, enabling slower lifting and travel speeds under heavy loads, and faster speeds when the load is lighter or absent. This is a groundbreaking and unprecedented solution in the crane industry.

The implemented solution provides the following benefits:

- Unlimited lifting height, depending on the number of rope layers wound on the drum,

- Reduced dimensions and weight of the hoist due to the shortened drum length,

- Improved safety and stability of the transported load thanks to the non-moving and non-rotating pulley block,

- Reduced operational times due to increased lifting and travel speeds when unloaded.

Applications:

- Industry: Efficient and safe lifting and transport of heavy loads,

- Construction: Handling of building materials and structural elements,

- Manufacturing: Precise movement of components, enhancing production efficiency and quality,

- Warehousing: Facilitating storage and movement of products and materials.

Model Applications:

- TOWER: Basic winch

- TOWER-E: Energy recovery module for grid return

- TOWER-D: Load-dependent lifting and travel speed adjustment module

- TOWER-P: Smooth travel and lifting module

- TOWER-S: Winch trolley module designed without welding technology

Marketing Materials – Winch with Multi-Layer Rope Guidance System

This project is co-financed by the European Regional Development Fund as part of the Smart Growth Operational Programme 2014-2020.

Project Number: POIR 01.01.01-00-1726/20-00