Parameter

|

Range

|

| Load capacity |

up to 500t |

| Span |

as per requirements

|

| Lifting height |

as per requirements

|

| Lifting speed |

as per requirements

|

| Trolley travel speed |

as per requirements

|

| Crane travel speed |

as per requirements |

| Control |

as per requirements

|

| Duty class (GNP) |

as per requirements |

Purpose

|

as per requirements |

Catalog number

|

SHN2

|

The table provides the main parameters that need to be provided to prepare a preliminary offer for a crane, and these parameters can be adjusted to the customer's needs.

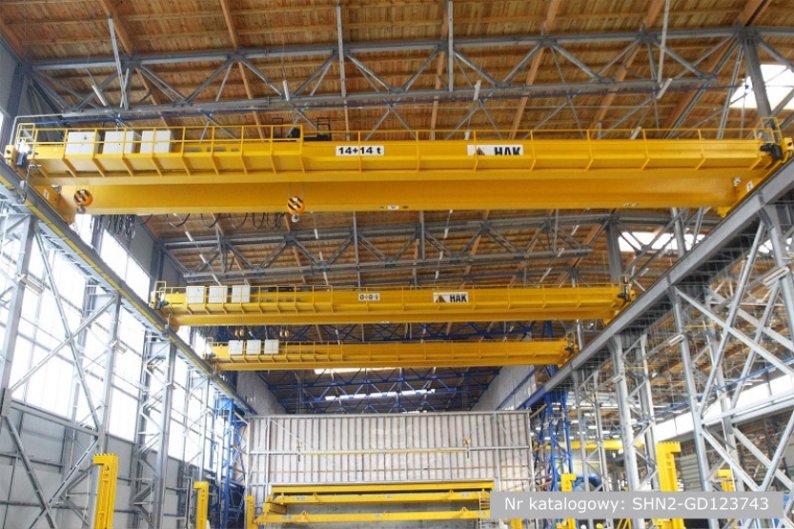

Double-girder overhead travelling cranes

Double-girder cranes are machines with very high load capacities. The double-girder construction allows for the use of advanced winches, columns, and specialized detachable lifting devices.

Applications:

- Transporting large, often non-standard loads in large areas of production facilities,

- Supporting processes in difficult conditions, such as foundries or steel mills,,

- Handling loads using specialized lifting solutions.

Double-girder overhead travelling cranes are a solution used across all industries. They are installed in production halls and warehouses and are also designed for use in open industrial areas.

The main component of a double-girder overhead crane is a bridge composed of two parallel girders supported by end trucks. The end trucks are equipped with travel mechanisms, allowing the crane to move along the runway. The runway for double-girder overhead cranes is mounted on a structure designed for this purpose, with adequate strength. One or more cranes of this type, equipped with anti-collision systems, can move along a single runway.

The basic equipment of double-girder cranes includes electric winches, and the control of the crane’s travel system and the load-lifting system is done via a radio control system. These cranes have a load capacity ranging from 1.6 tons to 500 tons, with a bridge span of up to 35 meters.

What kind of double-girder crane does your company need?

The most important aspect is that the crane is tailored to the specific requirements of your business. As a leader in crane manufacturing, we can provide that – use our offer, and we will design a device with precisely defined parameters for you.

How do our double-girder cranes work?

Double-girder overhead travelling cranes are close-quarters transport devices featuring a double-girder bridge supported by end trucks. They are equipped with a travel system that allows them to move along the runway..

What sets our double-girder cranes apart? Above all, ease of use. The winches responsible for transporting goods are controlled via a radio system – making it simple and intuitive.

What can we do for you as a producer of overhead cranes?

The effectiveness of a double-girder overhead crane in your production facility depends on its parameters. However, it may happen that standard models do not meet your company’s needs.

We have the solution! Since we fully control the crane manufacturing process at every stage, we can create a device with the parameters you specify. You can decide on the most important factors:

- Maximum load capacity;

- Hoist travel speed;

- Hoist lifting height;

- Span;

- Duty class (GNP).

What benefits will your company gain from a custom-designed double-girder crane?

Double-girder overhead travelling cranes have wide applications – our customers use them in warehouses, loading facilities, and production halls. They are suitable for both light and heavy industries. As one of the most popular close-quarters transport devices, they streamline operations, automate processes, and ensure safety during internal transport – all without taking up floor space.

By tailoring the crane’s parameters to your needs, your company can also take full

advantage of these benefits. Manufactured in our own production facility, the crane will be

prepared to handle loads of a specified weight. It will fit perfectly into your warehouse,

workshop, or production hall, allowing you to increase the efficiency of your operations from

day one.

Gain a competitive advantage by working with us – the leader in custom-made equipment production. Contact us through the form on our website, and we’ll reach out to discuss the details!

Together with overhead cranes, we provide complete power systems and crane equipment, including grabs, buckets, spreader bars, and lifting clamps. In addition to installing and commissioning overhead cranes, we also arrange crane inspection by UDT (Office of Technical Inspection) and provide training on crane operation. At our company, price is aligned with quality. All projects come with both warranty and post-warranty support, and we also offer maintenance services for overhead cranes from various manufacturers.