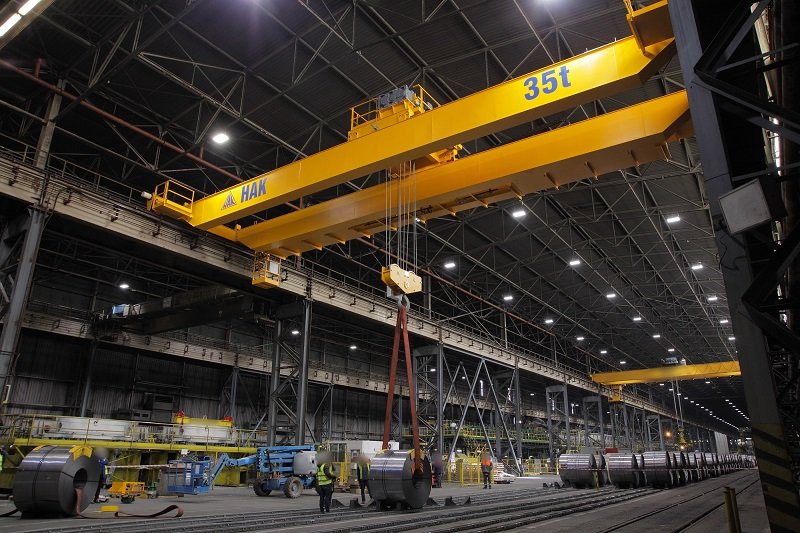

Industrial cranes with grabs for alternative fuel plant

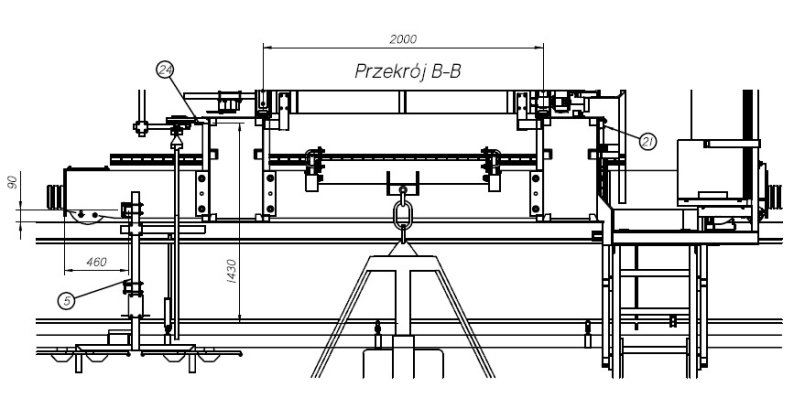

A system of two double-girder cranes equipped with two-shell electrohydraulic grabs, operating in automatic mode. Sensors and scanners mounted on the cranes ensure synchronized operation and even distribution of transported loads.

Applications:

- Transporting bulk materials in the chemical, energy, and mining industries,

- Homogenization, loading and unloading materials onto trucks, conveyors, or storage fields,

- Managing transport in areas with limited human accessibility.