- Crane tracks

- Grabs and clamps

- Lifting beams

- Hoists, winches, blocks, hooks

- Gantry hoists

- Jib cranes

- Equipment and spare parts

- Platforms and transport vehicles

- Lifts and forklifts

- Create your own lifting truck

- Manual Lifting Truck for Ring Assembly Q=230 kg

- Manual Lifting Truck for Injection Mould Assembly Q=300 kg

- Manual Lifting Truck for Injection Mould Assembly Q=300 kg

- Electric Lifting Truck for Vehicle Component Assembly Q=70kg

- Electric Lifting Truck for Injection Mold Assembly Q=100kg

- Electric lifting truck for vehicle component assembly Q=200kg

- Electric lifting truck for bioreactor assembly Q=350kg

- Electric lifting truck for bioreactor assembly Q=450kg

- Electric lifting truck for electrical cabinet assembly Q=450kg

- Electric lifting truck for coil assembly Q=1000kg

- Electric lifting truck for coil assembly Q=1000kg

- Electric lifting truck for rotary assembly Q=1200kg

- Electric lifting truck for vehicle component assembly Q=1300kg

- Electric lifting truck Q=2t

- Automation of Production Processes

- Special technical solutions

- Designs and expertise

- Transborders platforms

- Rotators

- Welded steel structures

- Inspections and maintenance

Industrial cranes

|

PROFESSIONAL CRANE SERVICES |

Learn more |

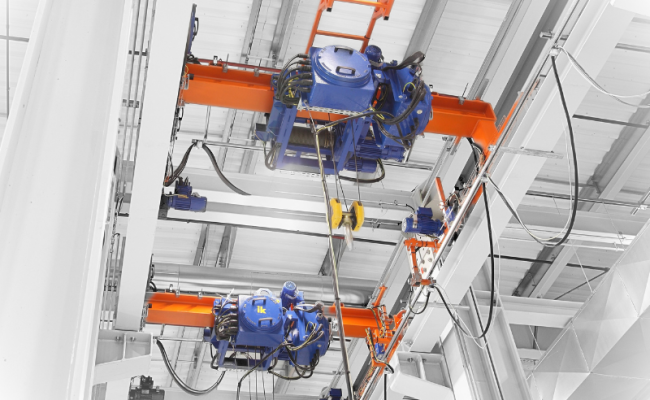

Technological processes carried out in enterprises often require the use of specialized solutions, strictly adapted to the loads and tasks performed. Many of these processes require the development of new, customized solutions that consider both production needs and issues related to safety and efficiency. One such solution is industrial cranes, also known as process or technological cranes.

Industrial cranes are one of the flagship products of HAK Company. These solutions are designed from scratch, following an on-site inspection, a study of the technological process, and an assessment of the client’s needs. Industrial cranes can include both overhead and gantry cranes—each of these devices can be precisely tailored to the type of load through permanent equipment with dedicated lifting accessories. Industrial cranes ensure proper operation in non-standard, challenging conditions, such as in explosion-hazard zones, extreme temperatures, high humidity or dust, and highly corrosive environments.

All overhead cranes are subject to the provisions of the Machinery Directive 2006/42/EC, and compliance is confirmed by the CE marking on the crane and the inclusion of a Declaration of Conformity.