- Crane tracks

- Grabs and clamps

- Lifting beams

- Hoists, winches, blocks, hooks

- Gantry hoists

- Jib cranes

- Equipment and spare parts

- Platforms and transport vehicles

- Lifts and forklifts

- Create your own lifting truck

- Manual Lifting Truck for Ring Assembly Q=230 kg

- Manual Lifting Truck for Injection Mould Assembly Q=300 kg

- Manual Lifting Truck for Injection Mould Assembly Q=300 kg

- Electric Lifting Truck for Vehicle Component Assembly Q=70kg

- Electric Lifting Truck for Injection Mold Assembly Q=100kg

- Electric lifting truck for vehicle component assembly Q=200kg

- Electric lifting truck for bioreactor assembly Q=350kg

- Electric lifting truck for bioreactor assembly Q=450kg

- Electric lifting truck for electrical cabinet assembly Q=450kg

- Electric lifting truck for coil assembly Q=1000kg

- Electric lifting truck for coil assembly Q=1000kg

- Electric lifting truck for rotary assembly Q=1200kg

- Electric lifting truck for vehicle component assembly Q=1300kg

- Electric lifting truck Q=2t

- Automation of Production Processes

- Special technical solutions

- Designs and expertise

- Transborders platforms

- Rotators

- Welded steel structures

- Inspections and maintenance

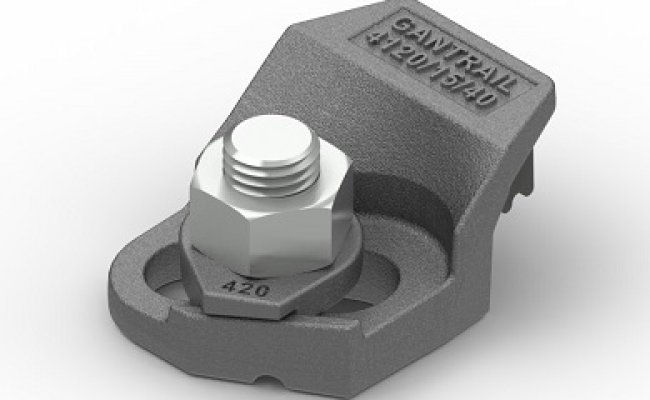

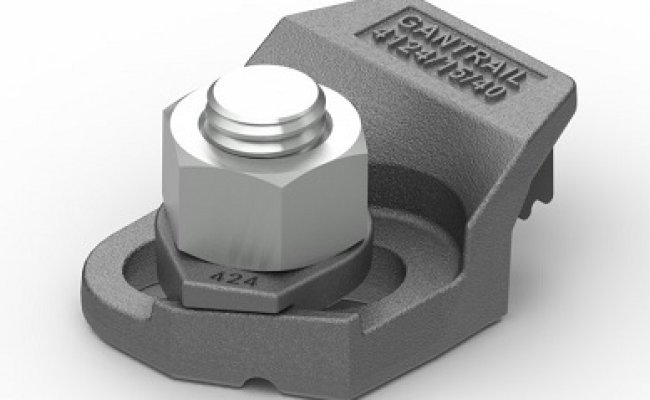

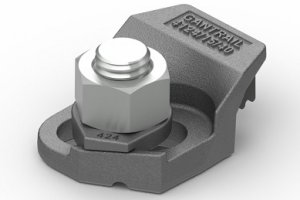

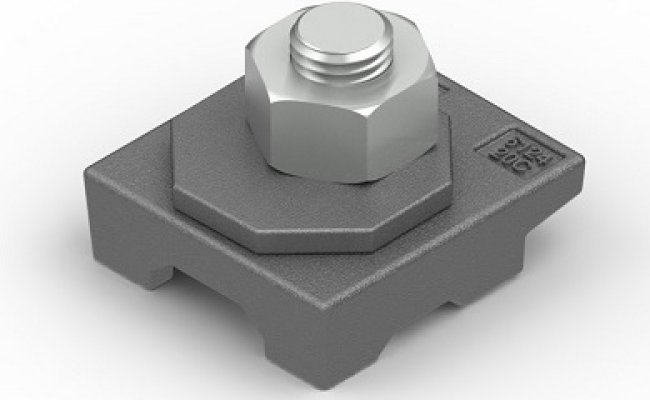

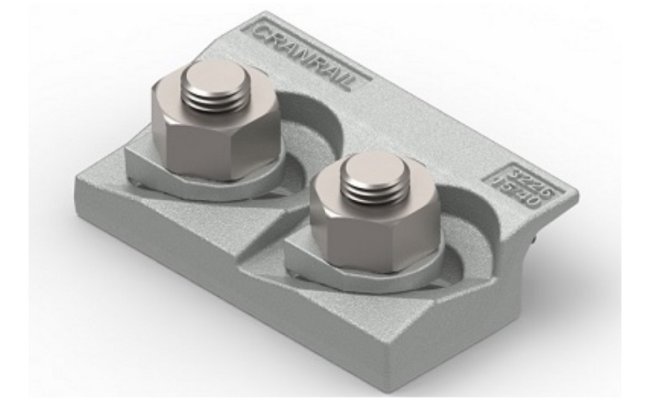

SCREW TERMINALS

Screw-on clamps – optimal in terms of technical and economic performance. A popular series used for lighter applications.

All clamps are equipped with rubber pads that allow for controlled pressure to be applied to the rail. The size of the pad is selected based on the characteristics of the clamp and rail. The pads ensure proper compression of the rail to the base, preventing contaminants from getting underneath the rail and stopping the rail from shifting along the track. The rubber element also allows for slight lifting of the rail due to the longitudinal wave that forms in the rail when a crane travels along the track, thereby reducing fatigue loads.