GANTRAIL System - Characteristics

HAK SP. z o.o. has been the exclusive Polish distributor of GANTRAIL rail fastening components for over 20 years. We specialize in selecting elements, designing gantry rail systems, and their comprehensive implementation. We offer technical support at every stage of the project.

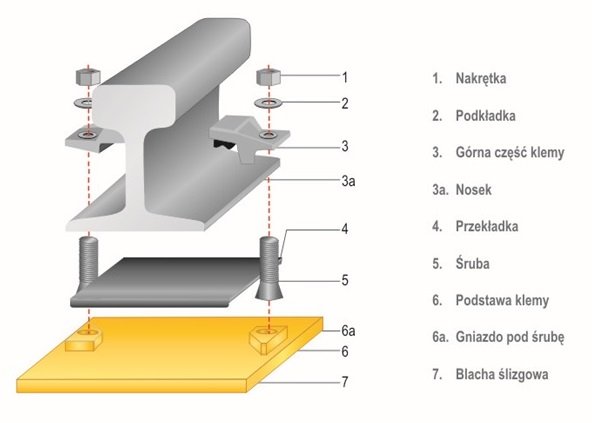

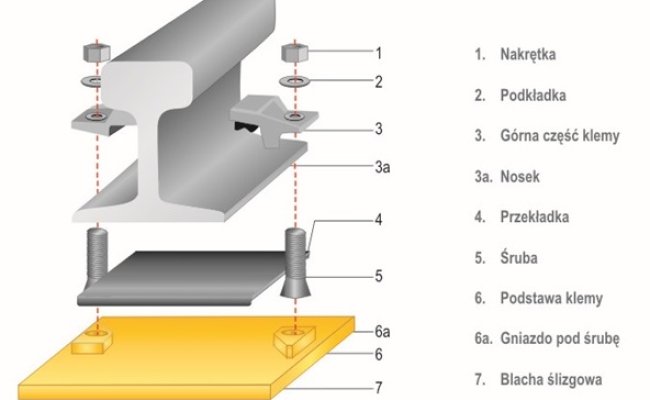

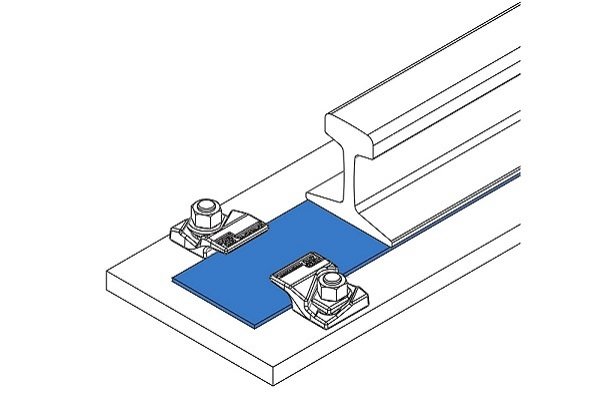

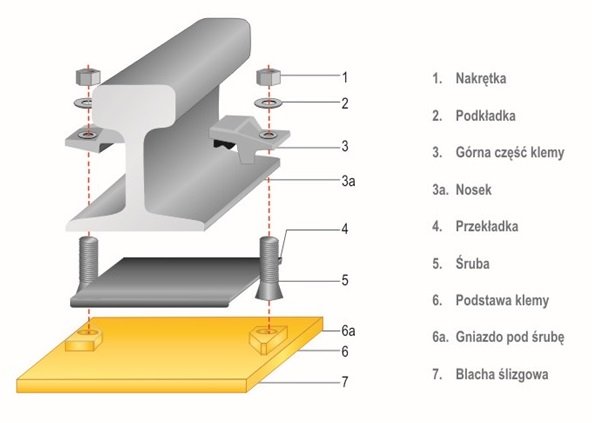

The GANTRAIL elastic rail fastening system consists of two main elements: rail clamps (brackets) and elastic pads. The clamps are equipped with a self-tightening mechanism for safety and elastomeric components that provide controlled rail clamping to prevent excessive rail migration.

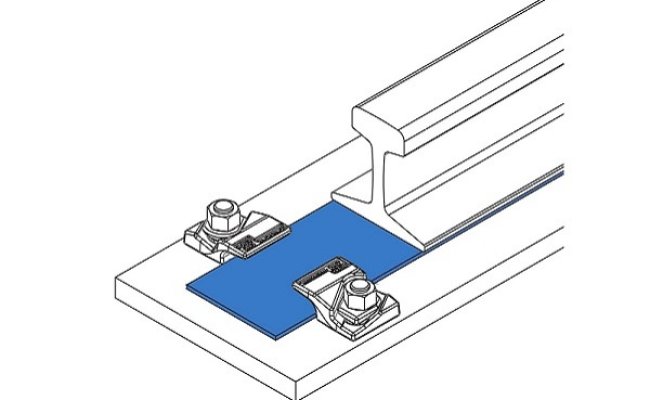

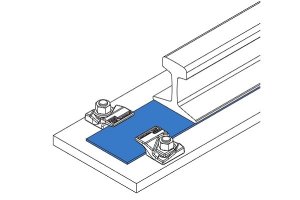

Gantry rail systems using GANTRAIL components can be installed in either elastic (with elastic pads under the rail) or semi-elastic (without elastic pads under the rail) modes.

Welded Clamps, Bolted Clamps, and Elastic Pads

Clamps are available in two versions: welded and bolted, allowing for the selection of the appropriate installation method based on existing requirements. The choice between bolted and welded clamps is often based on industry practice and preferences. Bolted clamps are economical and convenient but are intended for devices with significantly lower load capacities. In heavy industries such as steel and aluminum production, welded clamps are typically used, while lighter applications, such as industrial buildings and high-bay warehouses, usually employ bolted clamps. Elastic pads, located under the rail, are also available in various versions, adapted to the rail mounting method.

Elastic Rail Fastening System - Advantages

The Gantrail system allows for smooth adjustment, enabling precise rail positioning. The combination of rail clamps and elastic pads is designed to handle very high forces generated by moving gantries under full load. The system is compatible with every type of clamp.

STIFF RAIL FASTENING METHOD

|

ELASTIC RAIL FASTENING METHOD

|

- No adjustment of rail position

- Impacts at rail joints

- Uneven wear on the rail head

- High stress concentration under the rail base

- Premature rail wear

- Deformation of the rail head

- Rapid fatigue of gantry beams

|

- Continuous rail position adjustment

- Significant reduction in vibrations and oscillations

- Noise reduction

- Decreased stress under the rail base

- Increased resistance to fatigue loads

- Elimination of substrate wear

- Extended lifespan of the track and drive mechanism

|