- Crane tracks

- Grabs and clamps

- Lifting beams

- Hoists, winches, blocks, hooks

- Gantry hoists

- Jib cranes

- Equipment and spare parts

- Platforms and transport vehicles

- Lifts and forklifts

- Create your own lifting truck

- Manual Lifting Truck for Ring Assembly Q=230 kg

- Manual Lifting Truck for Injection Mould Assembly Q=300 kg

- Manual Lifting Truck for Injection Mould Assembly Q=300 kg

- Electric Lifting Truck for Vehicle Component Assembly Q=70kg

- Electric Lifting Truck for Injection Mold Assembly Q=100kg

- Electric lifting truck for vehicle component assembly Q=200kg

- Electric lifting truck for bioreactor assembly Q=350kg

- Electric lifting truck for bioreactor assembly Q=450kg

- Electric lifting truck for electrical cabinet assembly Q=450kg

- Electric lifting truck for coil assembly Q=1000kg

- Electric lifting truck for coil assembly Q=1000kg

- Electric lifting truck for rotary assembly Q=1200kg

- Electric lifting truck for vehicle component assembly Q=1300kg

- Electric lifting truck Q=2t

- Automation of Production Processes

- Special technical solutions

- Designs and expertise

- Transborders platforms

- Rotators

- Welded steel structures

- Inspections and maintenance

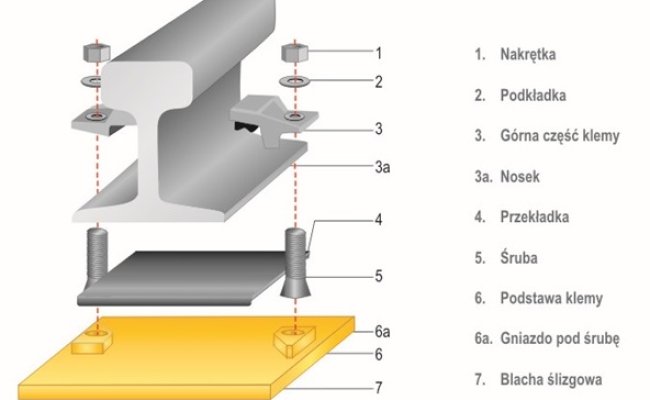

Flexible rail fastening systems GANTRAIL

HAK Sp. z o.o. is the exclusive Polish distributor of Gantrail brand components and technology for flexible rail fastening systems. Years of collaboration with the manufacturer and numerous completed projects enable us to provide expert knowledge in the construction of crane runways for various industries.

The flexible crane rail fastening system is designed to facilitate installation and reduce the operating costs of crane runways. It involves the use of flexible pads under the rail base and special clamps with an elastomer tip that secure the rail to the foundation. This solution ensures secure fastening while allowing lateral adjustment of the rail position during both installation and operation. The clamps are available in welded or bolted versions to be attached to the runway support structure. The system is complemented by the use of special mineral or resin compounds to fill the space between the leveled steel pads and the concrete foundation.