Technological System for Automatic Concrete Smoothing

APPLICATION

- In the production of precast concrete elements involving the smoothing of concrete mass,

- In processes for treating thick masses that require hardening through smoothing.

Got questions?

Contact us

Got questions?

Contact us

APPLICATION

|

System Parameters |

Value |

|

Device Parameters (dimensions, load capacity, control, power supply, working speeds) |

As required |

|

Catalog Number |

GD203151 |

APPLICATION

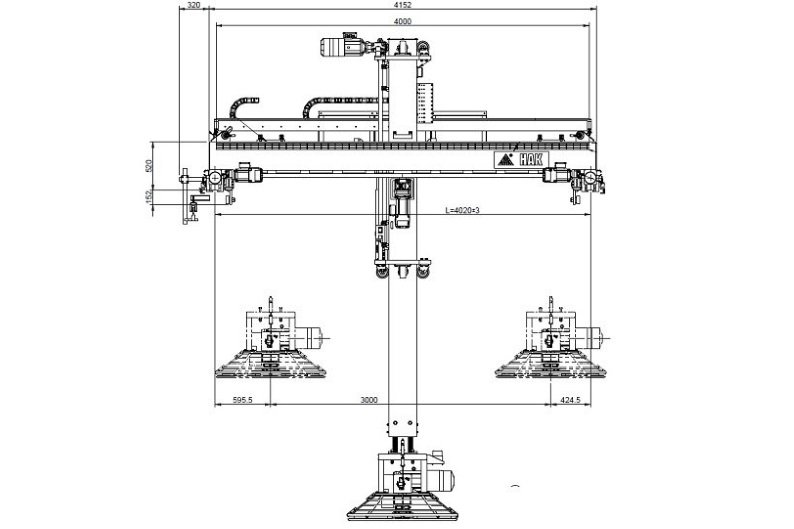

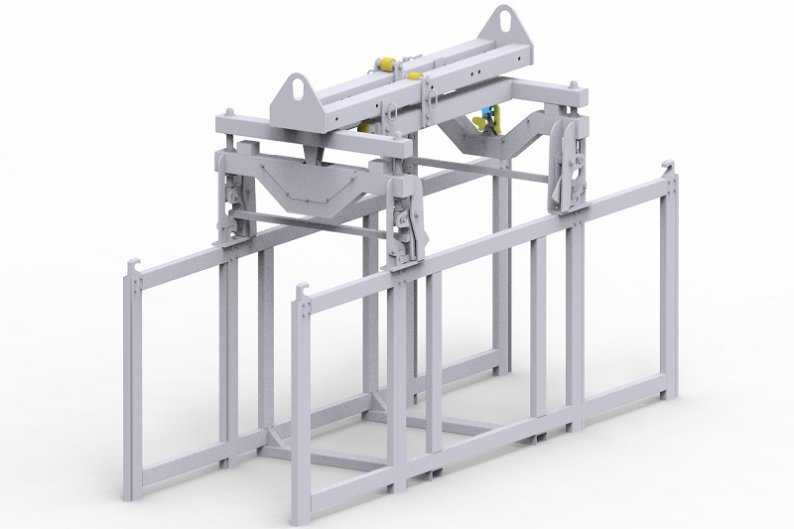

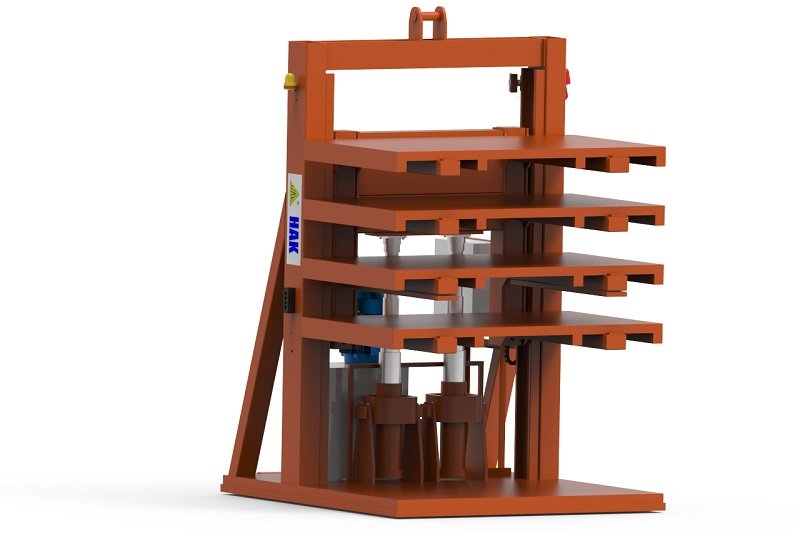

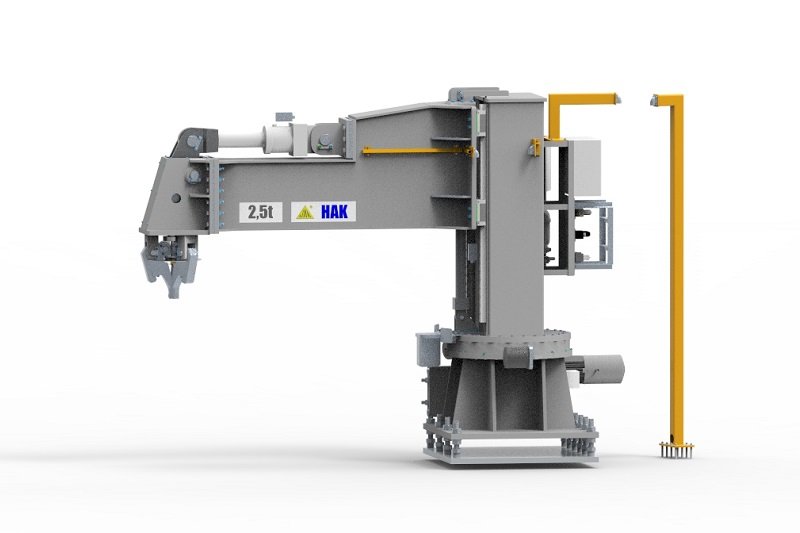

Technological System for Automatic Concrete Smoothing

The technological system for automatic concrete smoothing is an innovative solution that significantly improves this stage of the precast concrete production process.

The smoothing of concrete mass, carried out in factories during prefabrication as well as directly on construction sites, is a crucial part of hardening the concrete mass. It aims to increase product strength, enhance abrasion resistance, and reduce subsequent dusting. In construction processes, portable manual or machine trowels are used. The production of large-format precast concrete elements required the development of a comprehensive solution to facilitate this task over larger surfaces in production conditions, thus increasing efficiency and accuracy.

FEATURES OF THE AUTOMATIC CONCRETE SMOOTHING SYSTEM

BENEFITS OF USING THE SYSTEM

APPLICATION

Send an offer request

See also

Headquarters

Web store

8F Jerzmanowska street, 54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00

Headquarters

Web store

8F Jerzmanowska street,

54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00