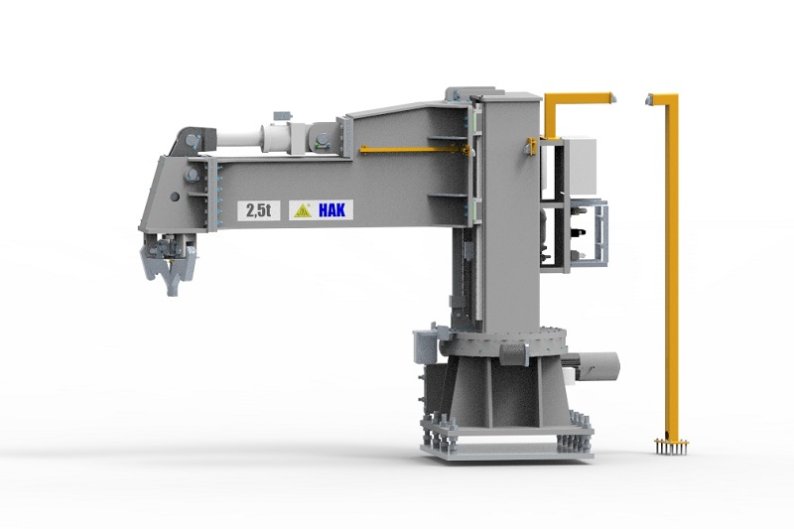

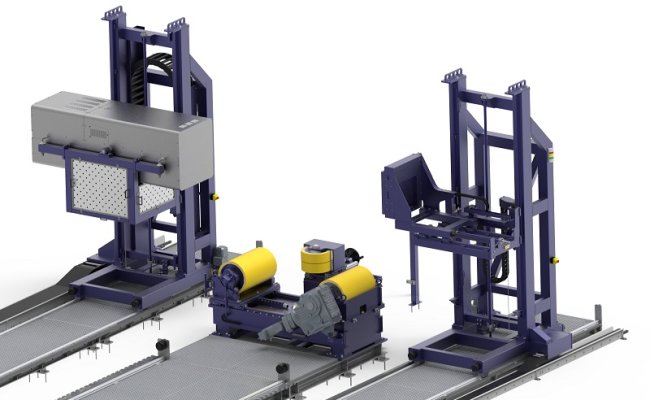

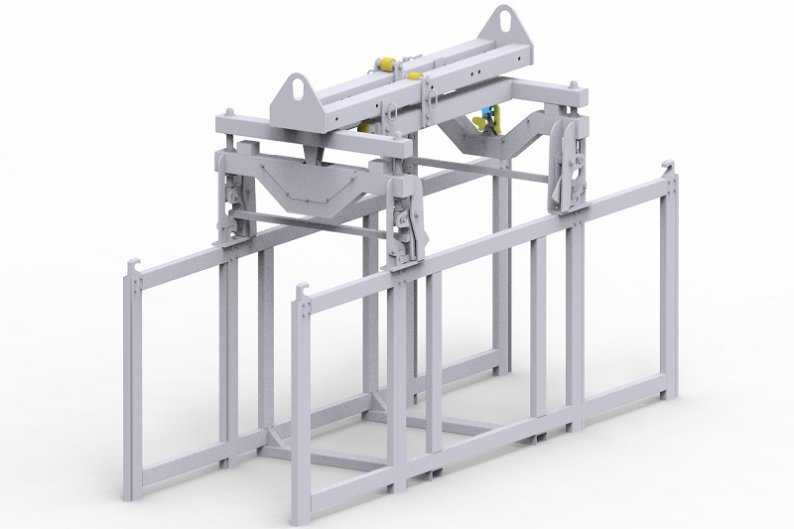

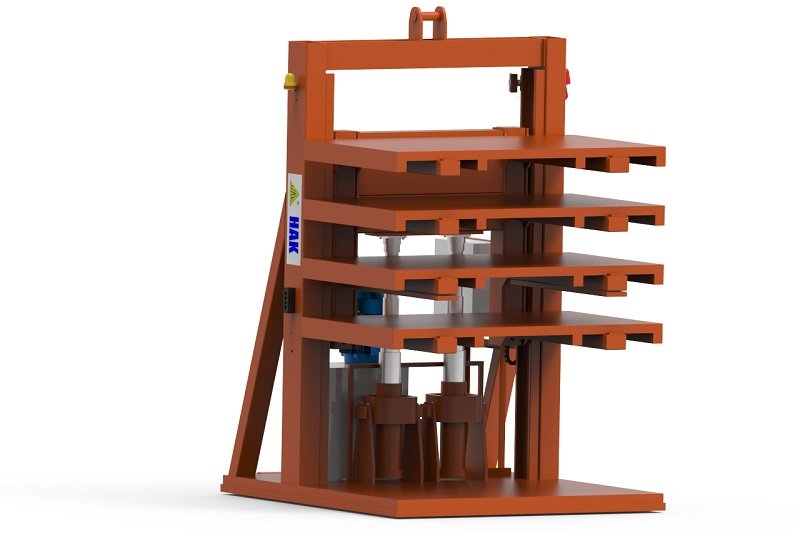

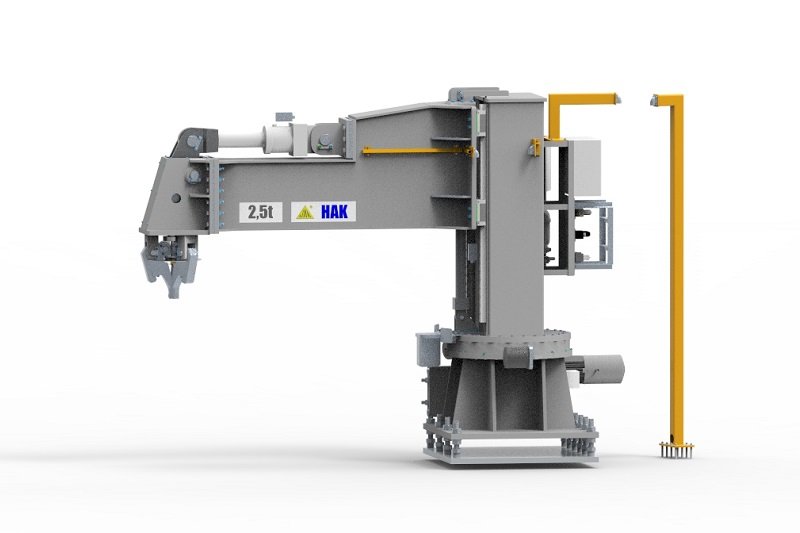

Spindle manipulator system

The manipulator system has been designed and manufactured to handle the transport of steel components undergoing metallurgical processing. The smooth adjustment of the manipulators allows for guiding the load along a line with a variable trajectory.

The process of moving steel components during high-temperature processing requires specialized solutions tailored to both the load parameters and the environmental conditions in which the transport activities are carried out. Metallurgical environments require particular attention—an example is the two spindle manipulators designed for handling processed components such as rings and forgings.

FEATURES OF THE SPINDLE MANIPULATOR SYSTEM

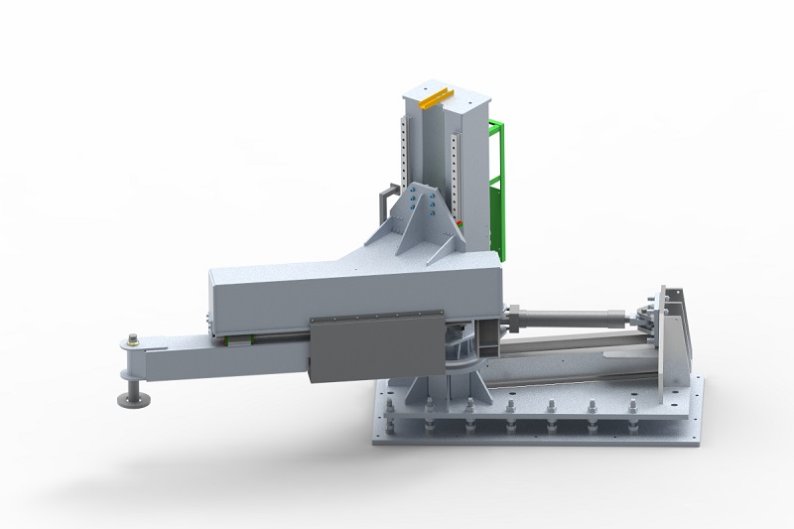

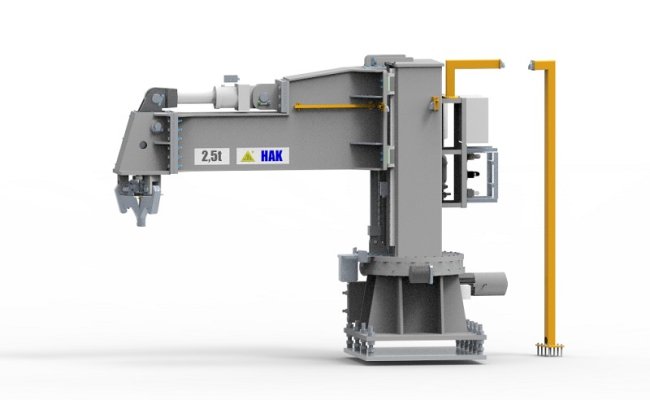

- the construction of the devices is based on jib crane design, enhanced with the capability to adjust the height and the reach of the arm,

- the booms of both manipulators operate with smoothly adjustable speed,

- the devices are equipped with movable jaws to grasp the load from the inside and a spindle to move the load across a flat surface,

- the manipulators are manufactured to operate in high temperatures and high dust environments,

- mechanisms for adjusting the height of the boom, extension of the arm, rotation angle, and operation of the jaws are hydraulically driven,

- operation of the manipulators can be controlled automatically or from a panel in the control cabin,

- the manipulators can be customized in various size configurations.

BENEFITS OF USING THE SYSTEM

- increased Efficiency: Streamlines the transport activities, enhancing processing efficiency,

- improved Accuracy: Enhances the precision of processes,

- automation: Automates the process,

- compactness: A comprehensive solution for quick installation and startup,

- increased Safety: Enhances workplace safety.

APPLICATION

- loading and transporting steel components in the form of rings and forgings between different stages of production and processing,

- handling and moving components between production, processing, and assembly stages.