Omnidirectional Transport System

APPLICATION

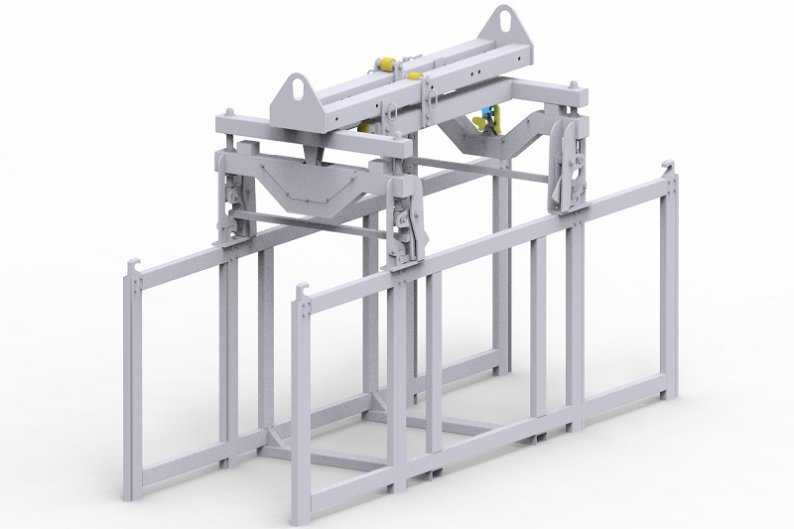

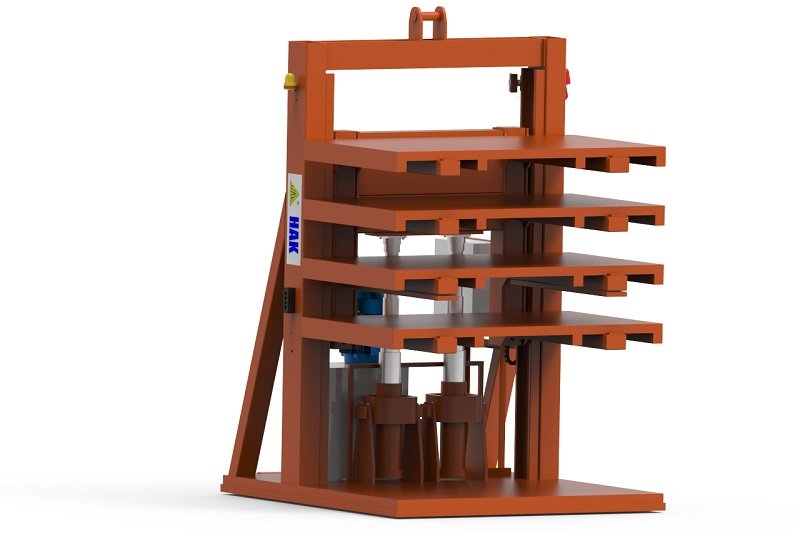

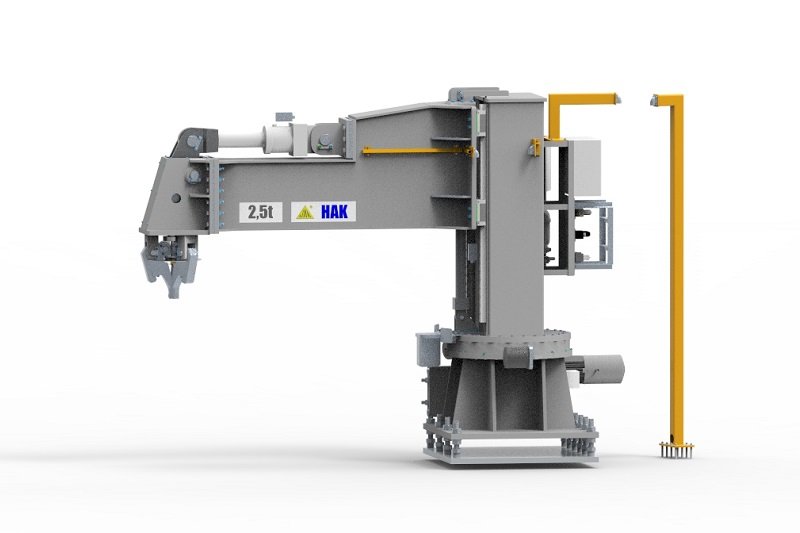

- The omnidirectional transporter with a hydraulic lift addresses specific needs related to the assembly of smaller components within larger structures.

Got questions?

Contact us

Got questions?

Contact us

APPLICATION

|

System Parameters |

Value |

|

Device Parameters (dimensions, load capacity, control, power supply, working speeds) |

As required |

|

Catalog Number |

NS172329 |

The omnidirectional transporter with a hydraulic lift is designed to meet the specific needs associated with assembling smaller components within larger structures. Key factors in assembly processes include mobility and precise positioning, which are crucial for achieving multiple contact points between the component being assembled and the overall structure. The omnidirectional transport system with a lift is the result of a detailed analysis of these requirements, manifested as a specially tailored, battery-powered electric transport platform. This solution aims to provide high mobility and precise positioning while maintaining the highest safety standards.

FEATURES OF THE OMNIDIRECTIONAL TRANSPORT SYSTEM

BENEFITS OF USING THE SYSTEM

APPLICATION

Send an offer request

See also

Headquarters

Web store

8F Jerzmanowska street, 54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00

Headquarters

Web store

8F Jerzmanowska street,

54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00