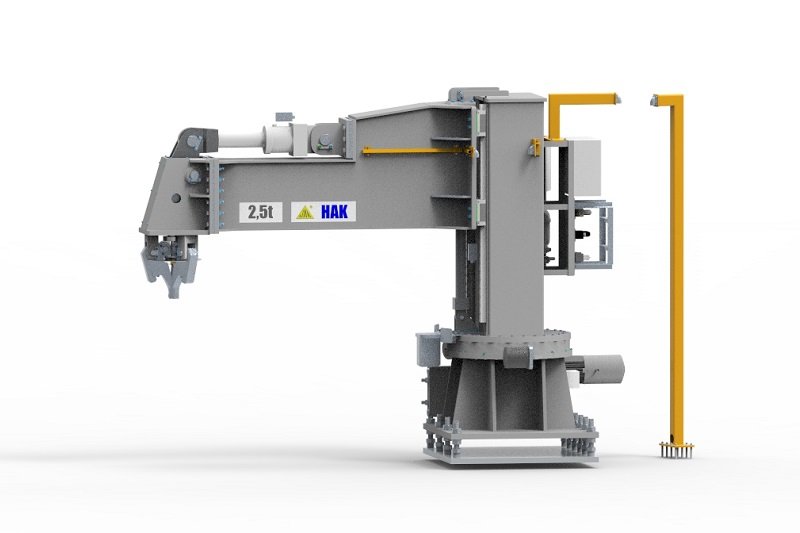

Manipulator for Steel Radiographic Testing

Radiographic testing (RT) is one of the most effective non-destructive testing (NDT) methods. The principle of detecting material discontinuities is based on the phenomenon of radiation intensity change as it passes through the test object, where various defects create areas of different thickness. Industrial radiography is particularly effective for detecting and locating internal inconsistencies. The X-ray testing manipulator is designed for managing this process within a closed chamber.

FEATURES OF THE STEEL X-RAY TESTING MANIPULATOR

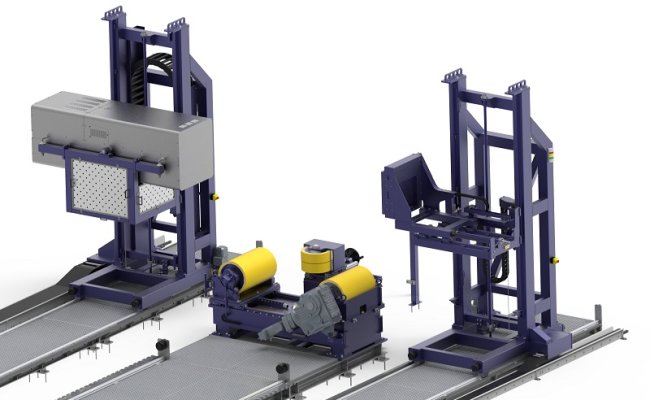

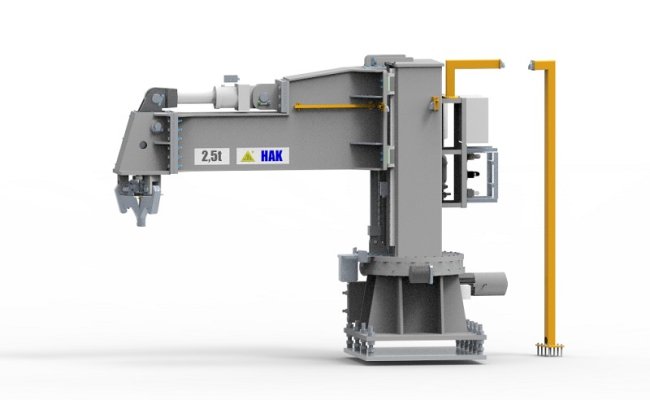

- The manipulator is mounted on a structure based on a column crane design with a mechanism for rotating the column around its own axis.

- The manipulator's structure moves along a dedicated track installed inside the chamber.

- An X-ray tube is mounted on the column with rotation and position adjustment capabilities.

- Device operation in the closed chamber is controlled via radio communication.

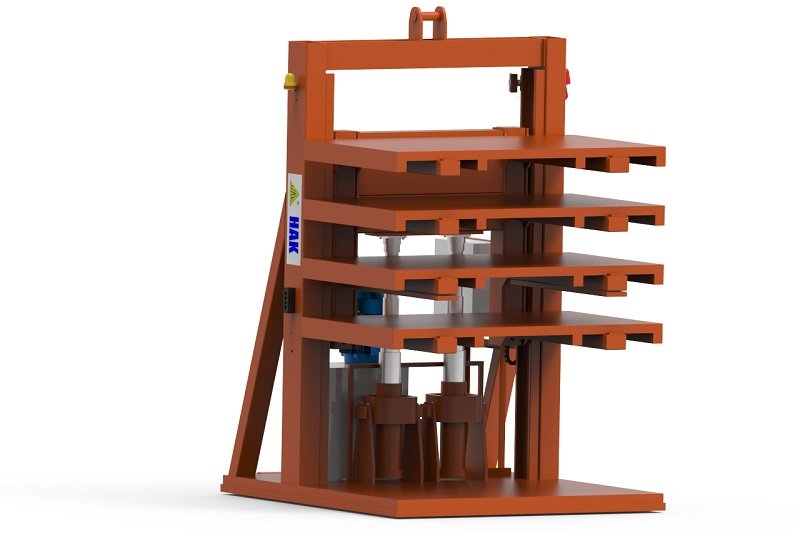

- The system can be constructed in various size and load capacity configurations.

BENEFITS OF USING THE SYSTEM

- Increased efficiency of steel testing by utilizing a device specifically designed for the process.

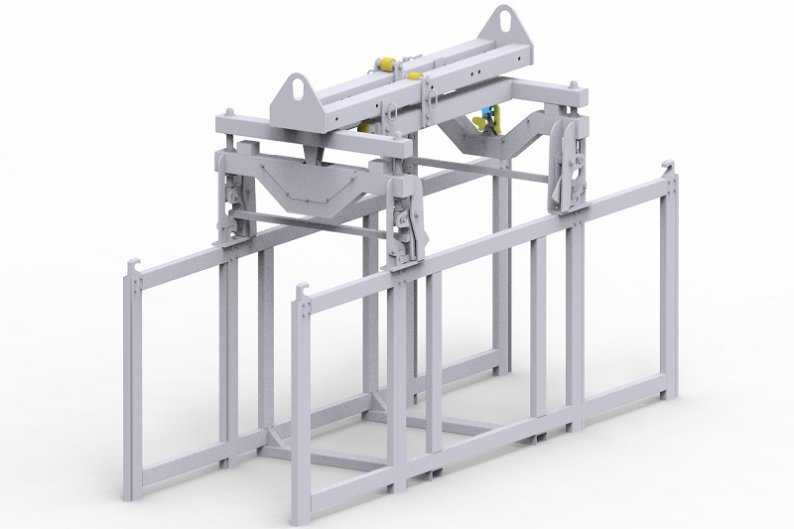

- Enhanced precision in load positioning during transport and testing.

- Automation of the positioning process, reducing the need for operator involvement.

- Compactness—a ready-to-use system for quick deployment.

- Increased workplace safety.