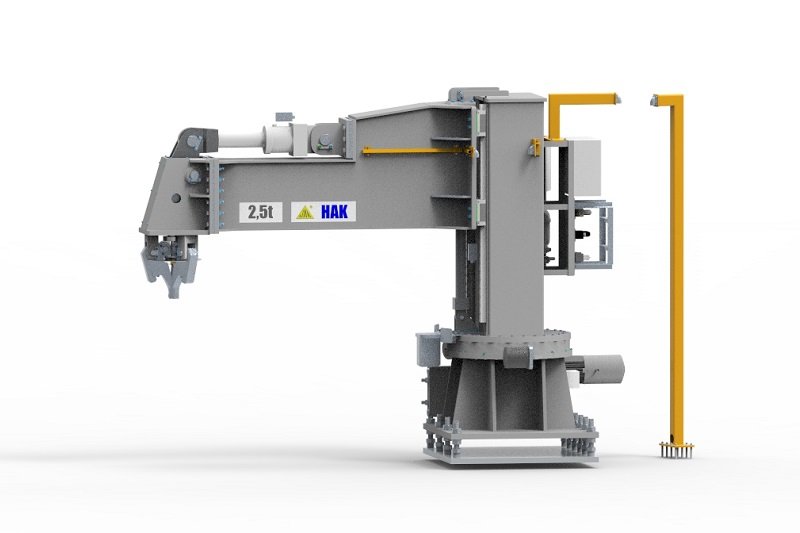

Hydraulic Wagon Straightening System

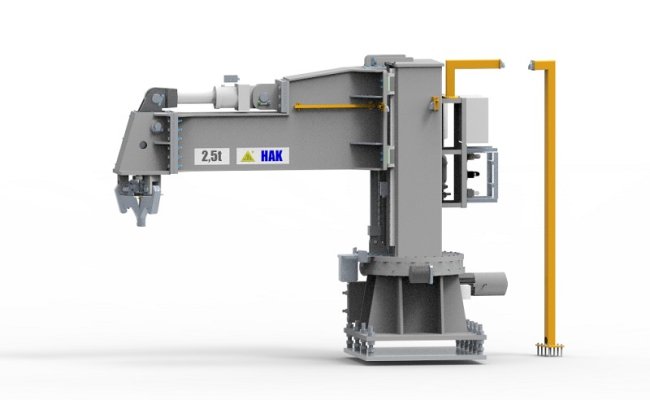

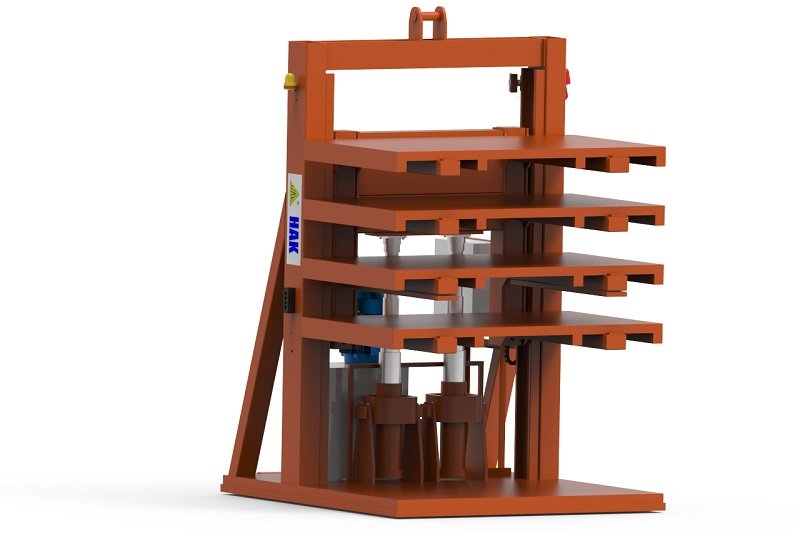

The process of straightening the walls and circumferences of coal wagons is a regular part of maintaining these transportation vehicles for coal and aggregates. The designed and manufactured device allows for "cold" straightening of metal sheeting and the upper circumferences of freight wagons. The process is carried out using hydraulic actuators mounted on supports, with adjustable positions and power settings.

FEATURES OF THE HYDRAULIC WAGON STRAIGHTENING SYSTEM

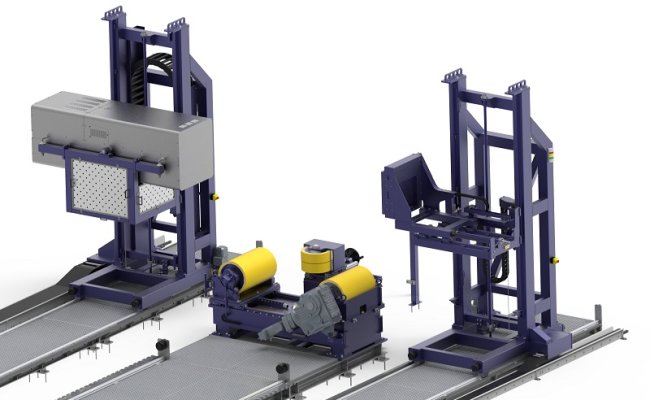

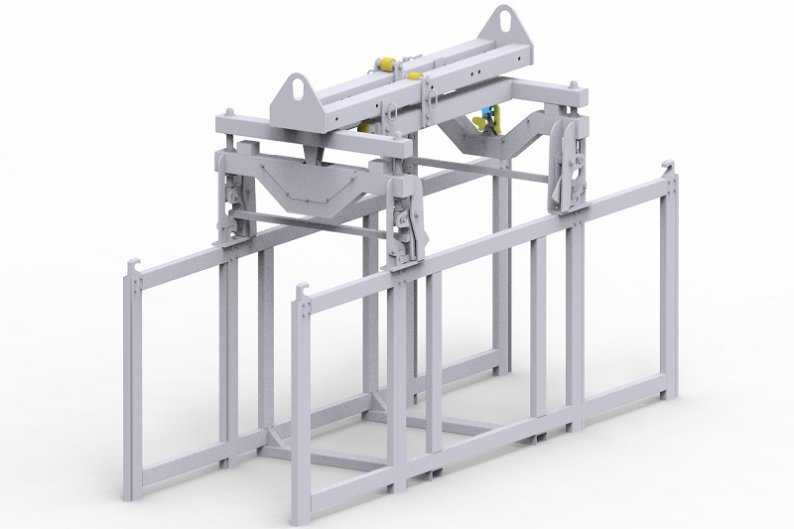

- The steel construction of the system is sized to encompass an entire wagon at once—during the straightening process, the immobilized wagon is inside the station and does not move.

- The individual elements of the structure are connected by lower beams, which support the track for the wagons, forming an integral part of the device.

- Hydraulic actuators are installed on the sides of the device, each with individual control, for direct mechanical straightening of wagon wall deformations—each support can be moved vertically and horizontally.

- An internal support, movable along the entire length of the wagon by gear motors, is used to block the wagon and reinforce and push out indentations in the walls and upper circumference.

- Service platforms on both sides of the device provide easy access for operators to the straightened wagons.

- A mechanical lock prevents the wagon from rolling in or out before all components are retracted to their resting positions.

- Emergency stop can be activated by the STOP switch.

- Device operation is controlled from a control panel (workstation), with internal support controlled wirelessly.

- The system can be made in various size and force configurations.

BENEFITS OF USING THE SYSTEM

- Increased efficiency of the wagon straightening process.

- Enhanced accuracy of the process.

- Automation of the process through a series of autonomous actions.

- Compactness—a comprehensive system of any size for quick installation and start-up.

- Increased workplace safety.