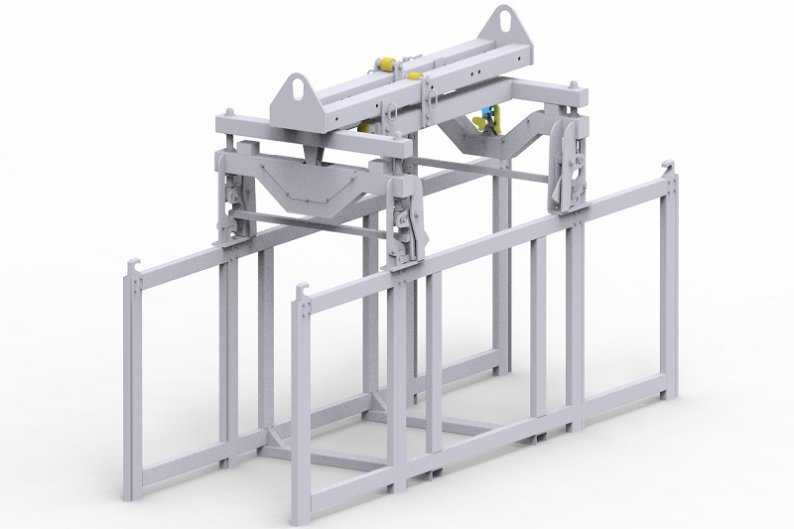

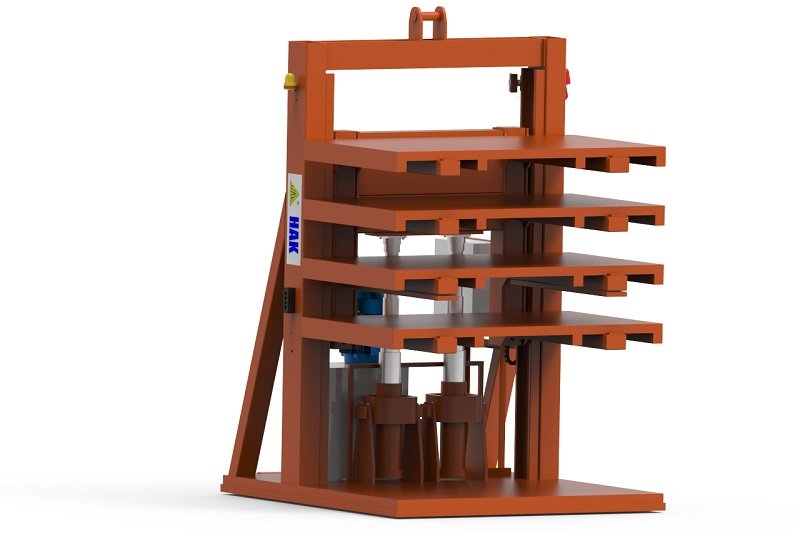

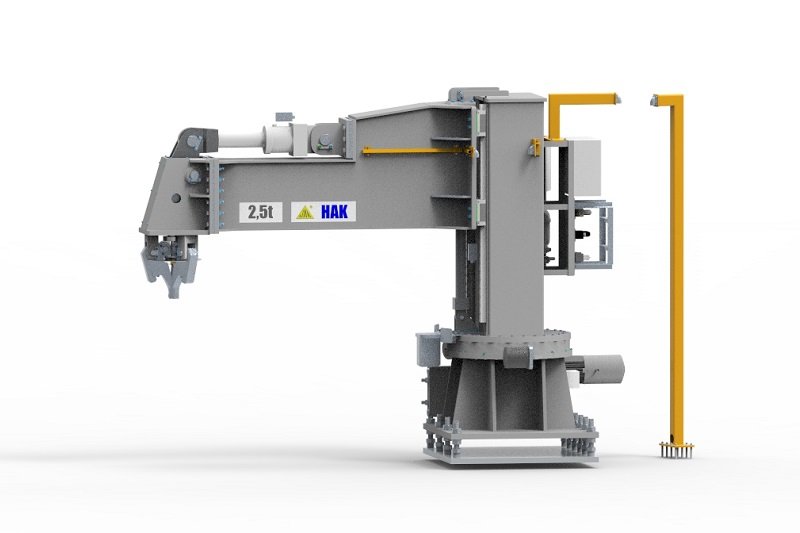

Automatic Load Leveling System

APPLICATION

- In the transportation of oversized and heavy loads requiring stable positioning during movement.

- In processes that require precise positioning of large, heavy loads.

Got questions?

Contact us

Got questions?

Contact us

APPLICATION

|

System Parameters |

Value |

|

Device Parameters (dimensions, load capacity, control, power supply, working speeds) |

As required |

|

Catalog Number |

GD100994 |

Transporting oversized loads often necessitates moving beyond standard solutions and developing a dedicated device with a broader range of functions and capabilities. For transporting large turbine rotors requiring stable, horizontal positioning during movement, an innovative transport system has been developed, based on a box-type spreader concept, supplemented with self-leveling systems.

FEATURES OF THE AUTOMATIC LOAD LEVELING SYSTEM

BENEFITS OF USING THE SYSTEM

APPLICATION

Send an offer request

See also

Headquarters

Web store

8F Jerzmanowska street, 54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00

Headquarters

Web store

8F Jerzmanowska street,

54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00