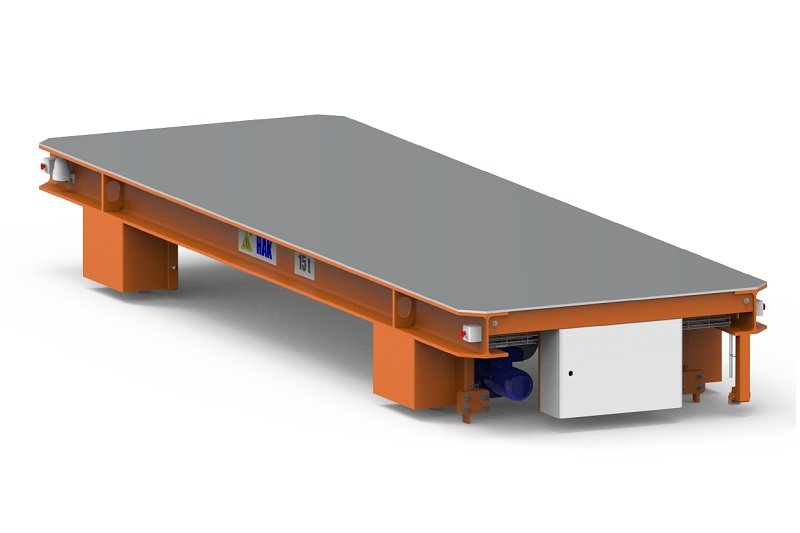

Mold Transport System

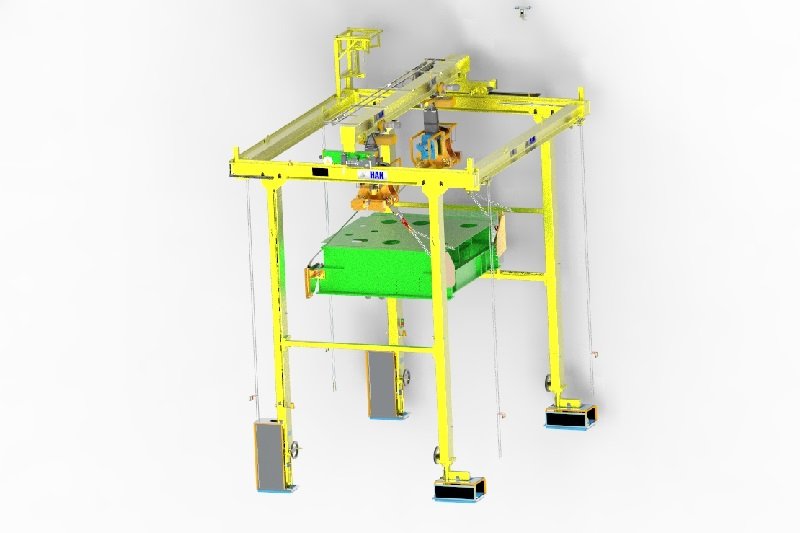

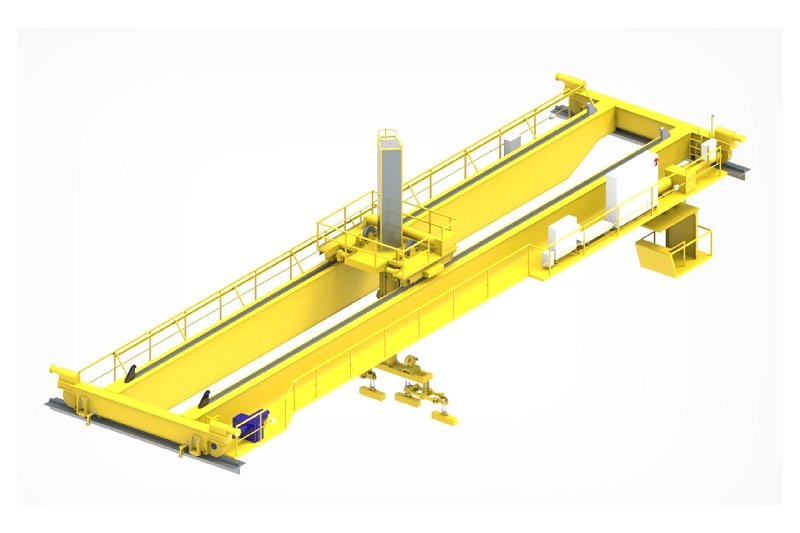

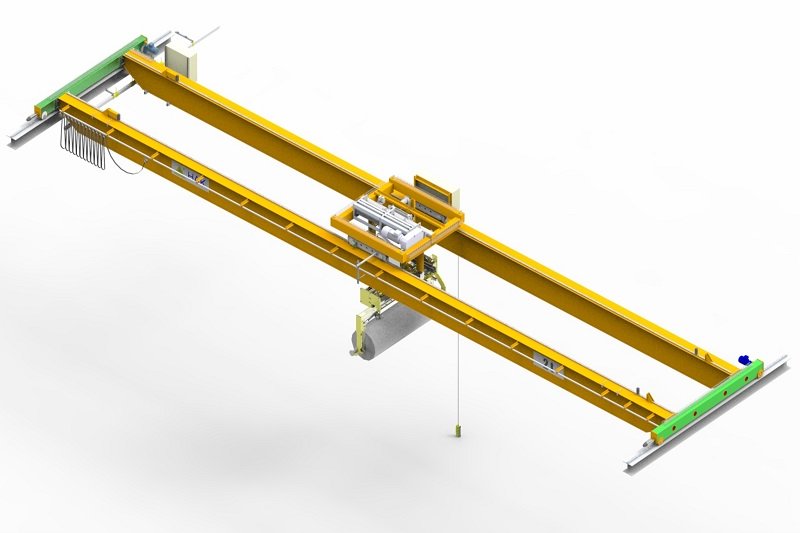

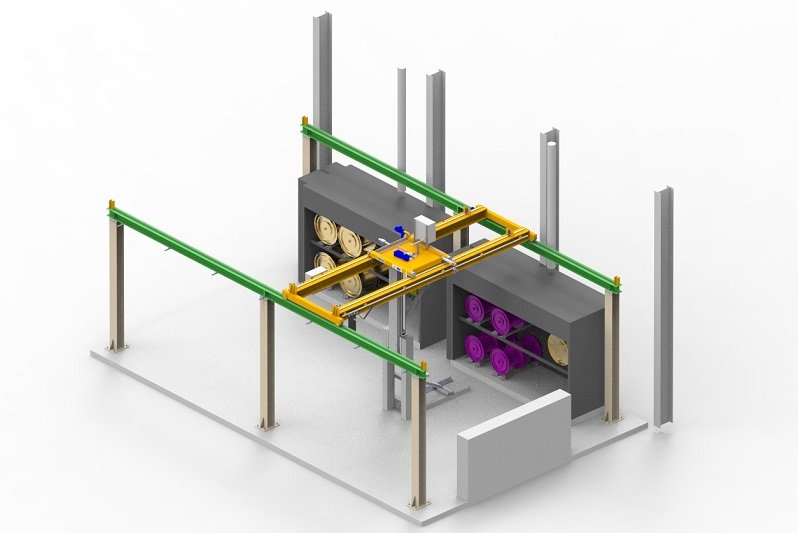

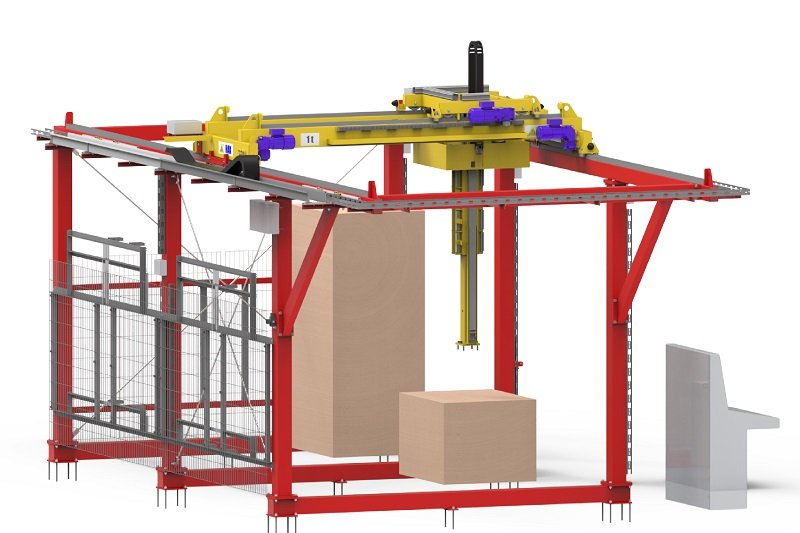

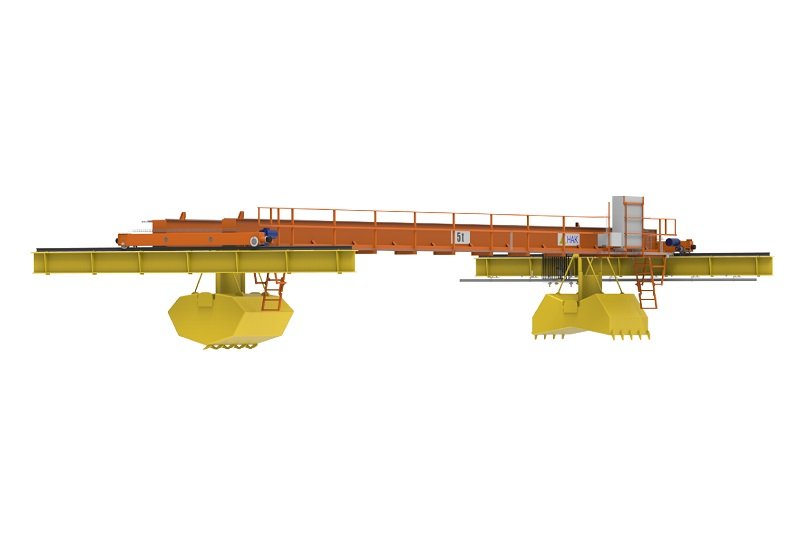

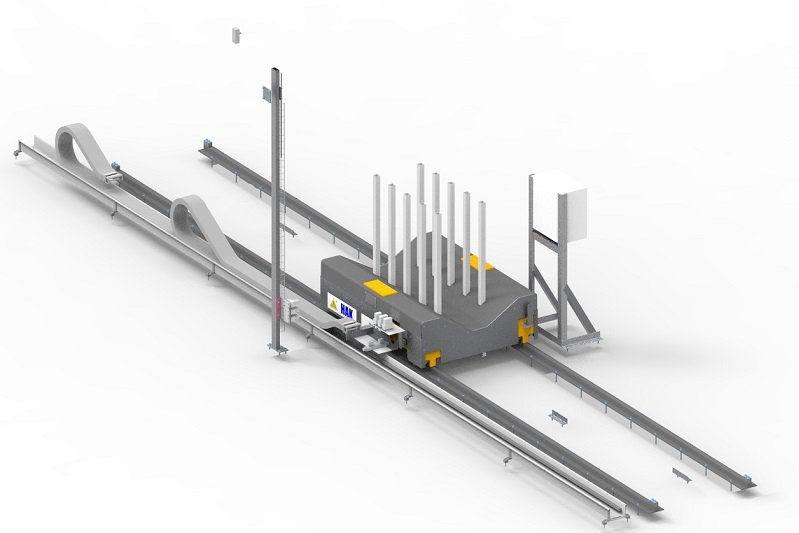

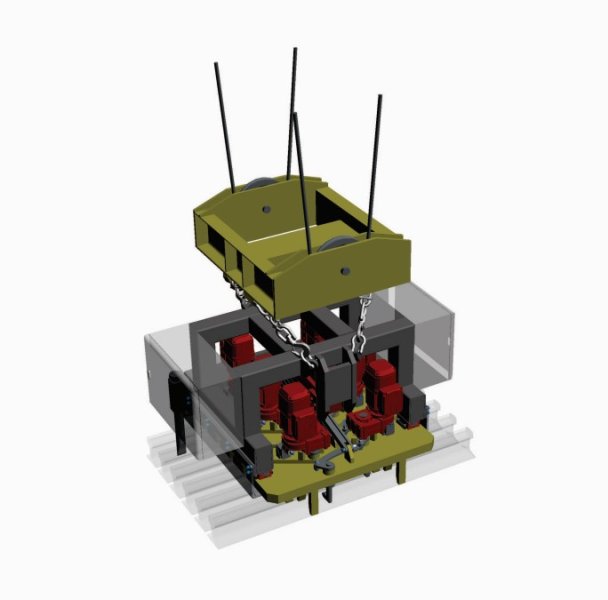

The mold transport system is designed to handle the circulation of molds and matrices in precast concrete production facilities.

Got questions?

Contact us

Got questions?

Contact us

The mold transport system is designed to handle the circulation of molds and matrices in precast concrete production facilities.

| Parameters | Value |

| Device Parameters (dimensions, load capacity, control, power supply, working speeds) |

as required |

| Catalog number | KN171324 |

The mold transport system is designed for managing the circulation of molds and matrices in precast concrete production facilities. The mold circulation system is based on the construction of transfer conveyors and is used for handling the transport of molds for concrete casting on roller conveyors within the production plant. The function of the transfer conveyor is to move molds on roller conveyors to selected other roller conveyors according to a programmed internal transport route. The conveyor system allows entry onto its roller conveyor from side roller conveyors installed in production halls, transfer of the mold along the conveyor to the axis of a selected other roller conveyor in the hall, and the removal of the mold from the conveyor’s roller conveyor onto that selected roller conveyor.

FEATURES OF THE MOLD TRANSPORT SYSTEM

BENEFITS OF USING THE SYSTEM

APPLICATION

Send an offer request

See also

Headquarters

Web store

8F Jerzmanowska street, 54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00

Headquarters

Web store

8F Jerzmanowska street,

54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00