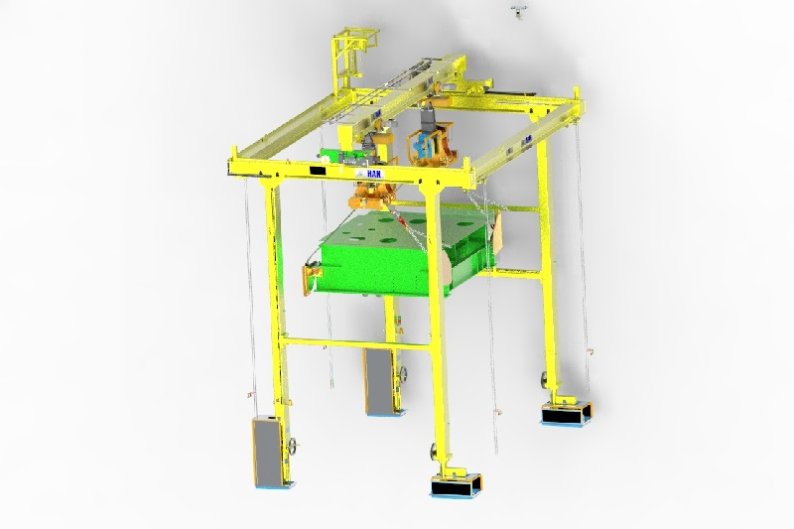

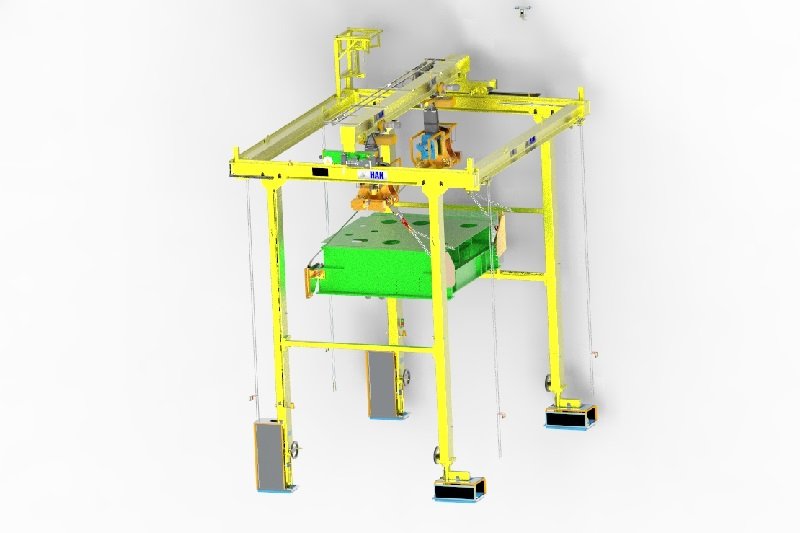

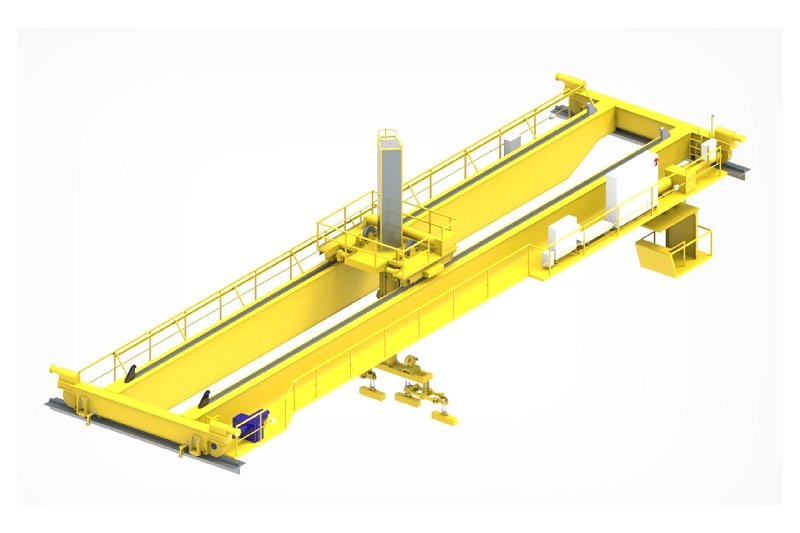

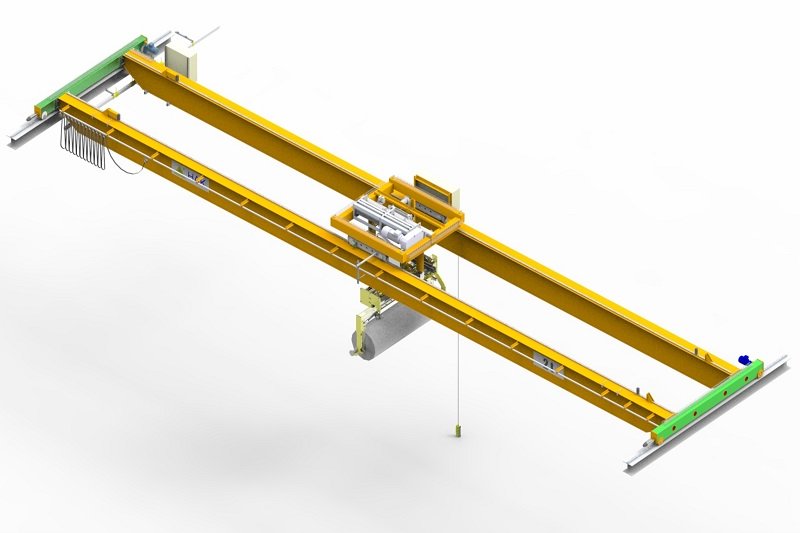

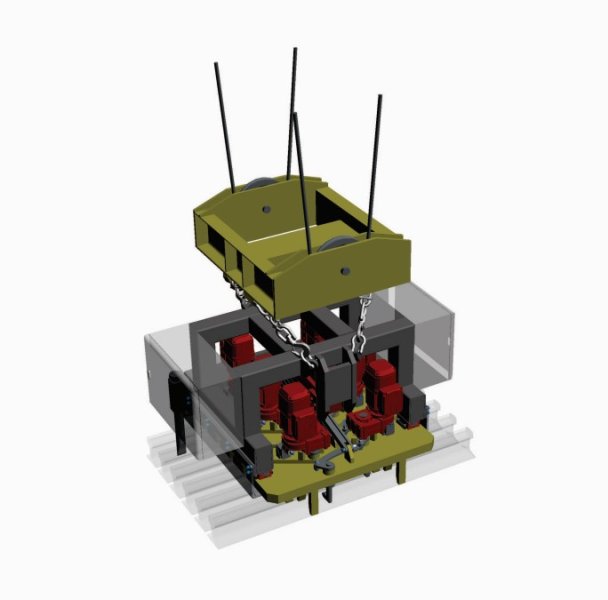

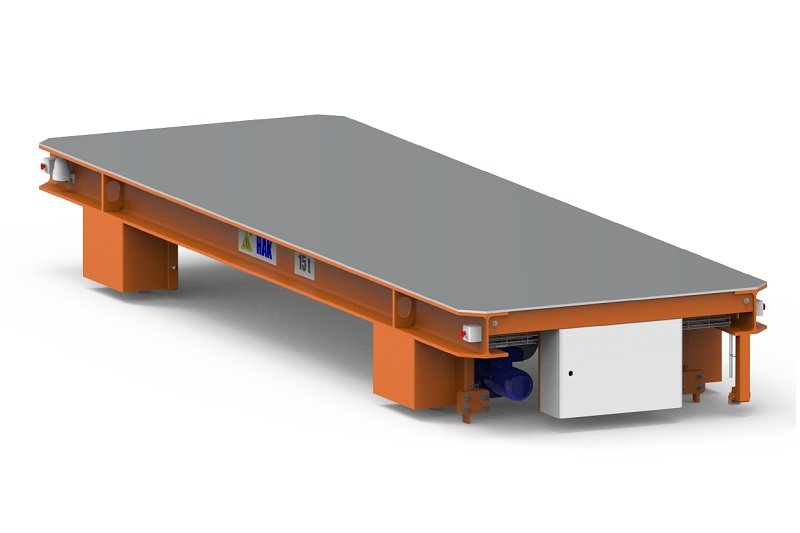

Mobile System with Crane for Component Transport

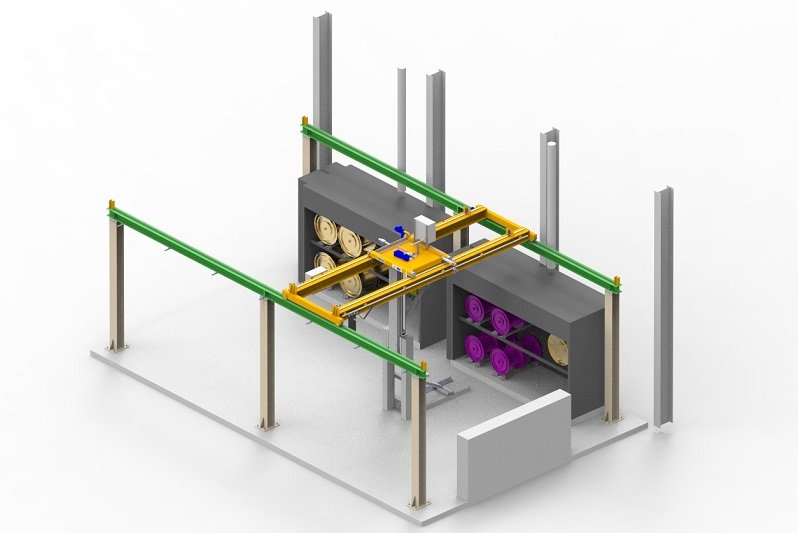

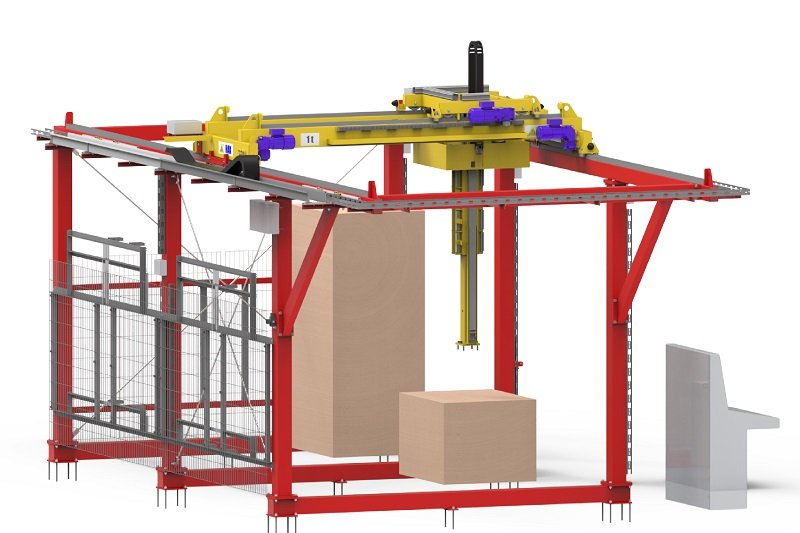

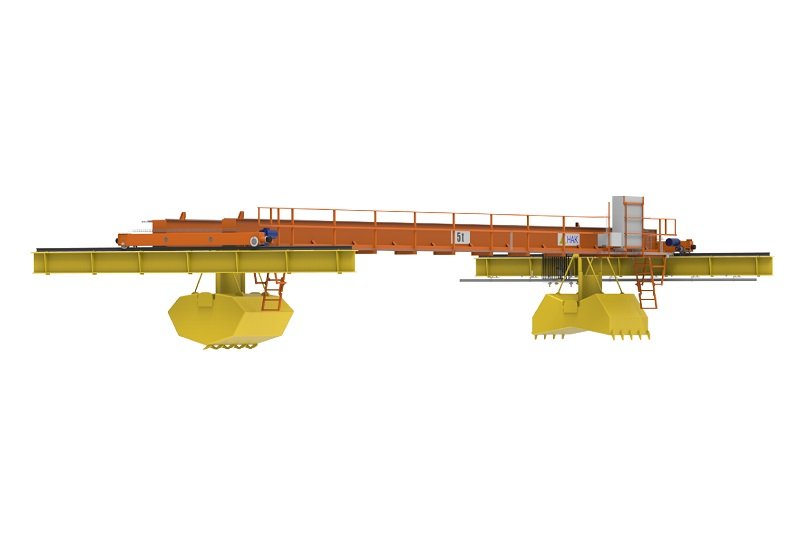

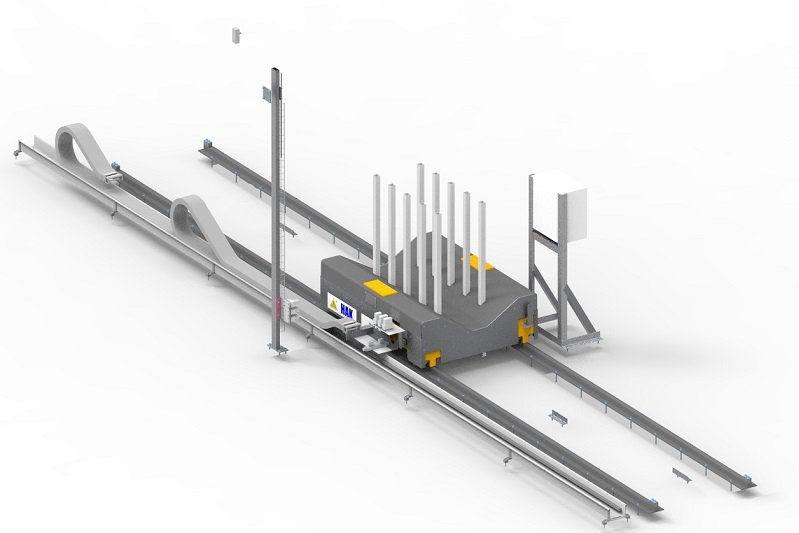

The mobile system with a crane is a solution consisting of nine devices designed for the assembly process of large-scale machine components.

Got questions?

Contact us

Got questions?

Contact us

The mobile system with a crane is a solution consisting of nine devices designed for the assembly process of large-scale machine components.

| Parameters | Value |

| Device Parameters (dimensions, load capacity, control, power supply, working speeds) |

as required |

| Catalog Number | WR151887 |

The assembly of large-scale machinery and machine components often requires custom solutions for lifting, transporting, and manipulating loads. These solutions must account for both the type and dimensions of the transported loads and the processing and assembly technologies used, which require specific functionalities from transport systems. This solution comprises nine mobile units equipped with cranes, intended for the positioning and assembly of generators.

FEATURES OF THE MOBILE SYSTEM WITH CRANE FOR COMPONENT TRANSPORT

BENEFITS OF USING THE SYSTEM

APPLICATION

Send an offer request

See also

Headquarters

Web store

8F Jerzmanowska street, 54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00

Headquarters

Web store

8F Jerzmanowska street,

54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00