Process automation in a tram depot – integration of crane with traction power system

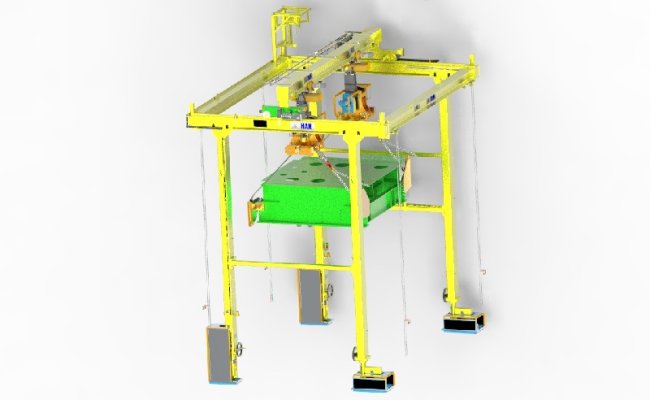

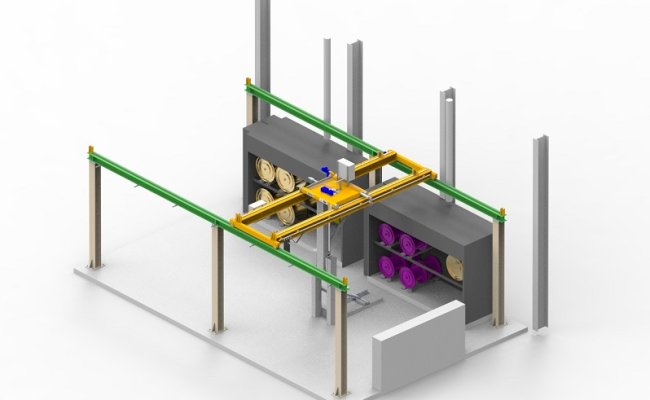

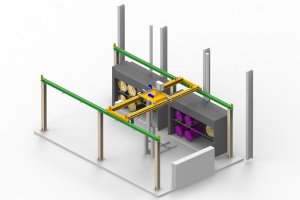

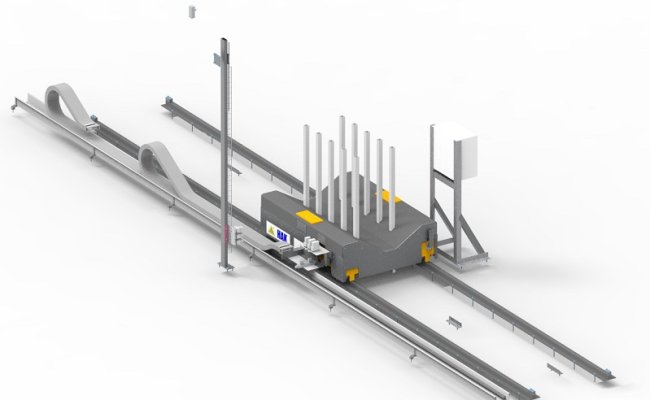

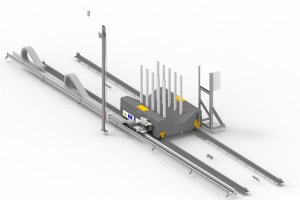

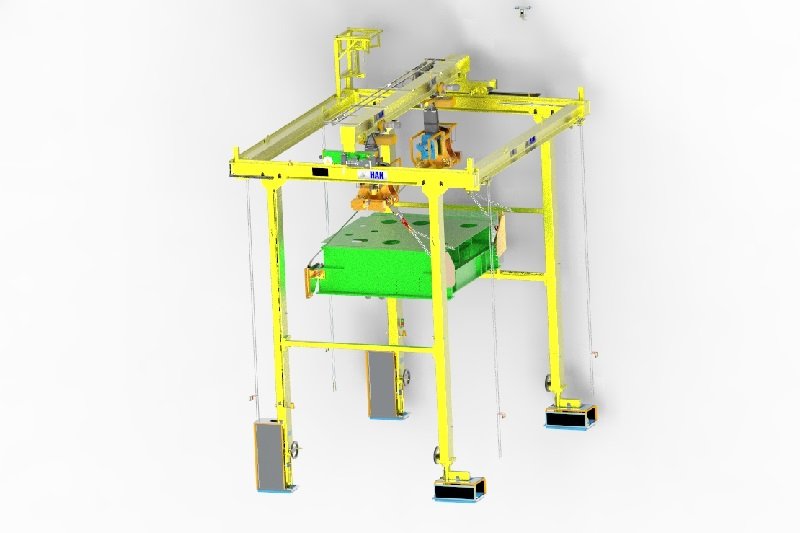

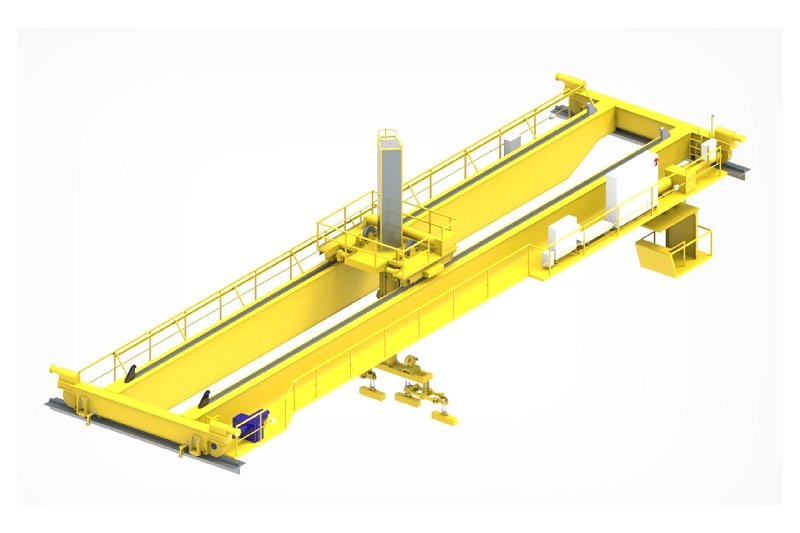

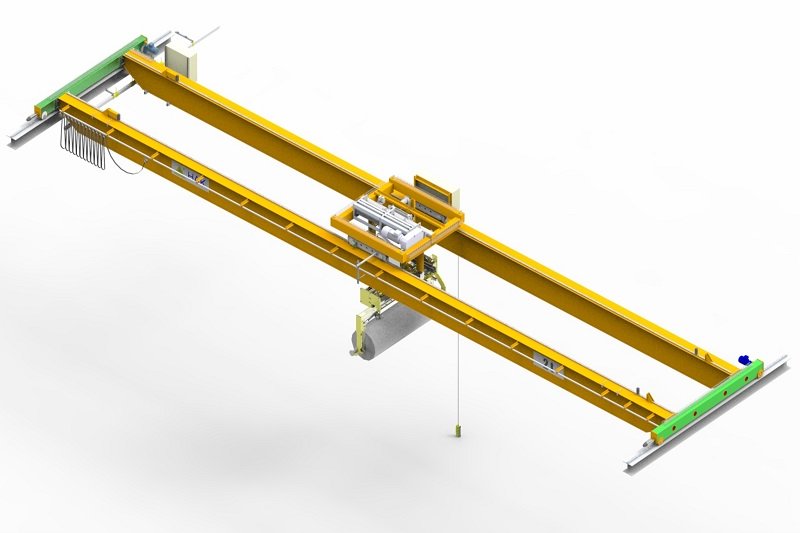

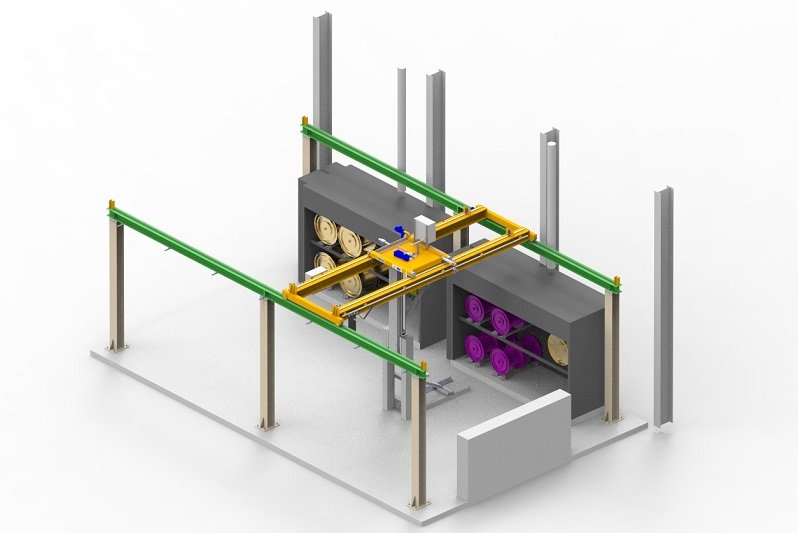

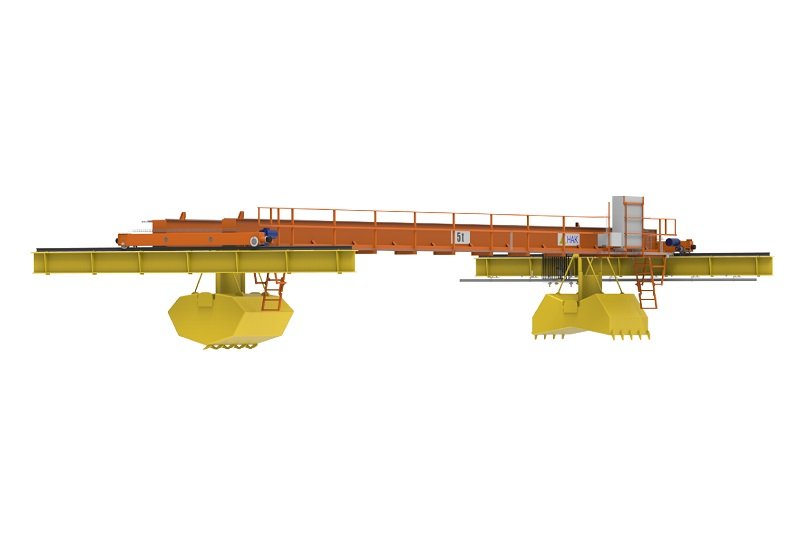

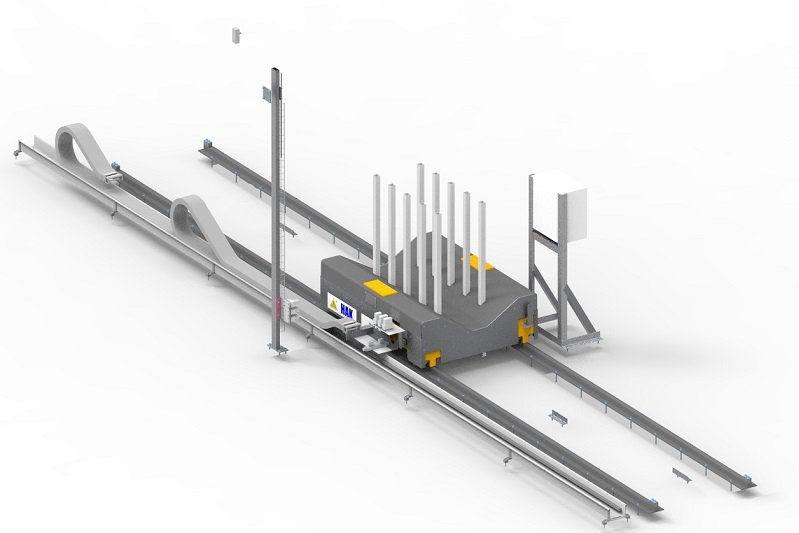

In one of the modern tram depots, HAK Ltd. carried out the comprehensive delivery and implementation of three single-girder overhead travelling cranes with a lifting capacity of 6.3 tons. One of the cranes – with a span of 20 meters – was additionally equipped with an advanced automation system that enables safe operation in conjunction with an active traction power system. The main goal of the project was to achieve full integration between crane movement and the track power supply status, which significantly increased safety and operational reliability in a shared space between lifting equipment and high-voltage electrical infrastructure.

Key features of the automated crane system for the depot:

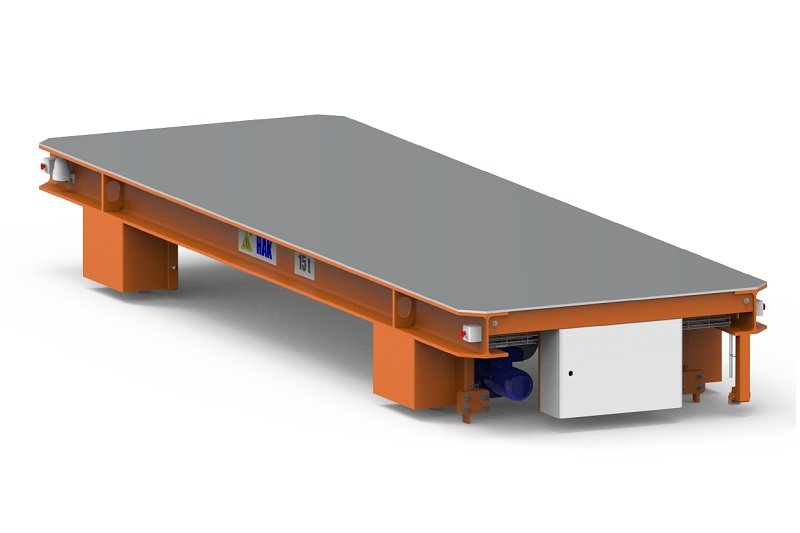

- three top-running single-girder cranes, Q = 6.3 t; spans: 20 m, 25.7 m, and 28.9 m,

- lifting height: 11.5 m,

- power supply: 400 V / 50 Hz; conductor rail length: 80 m,

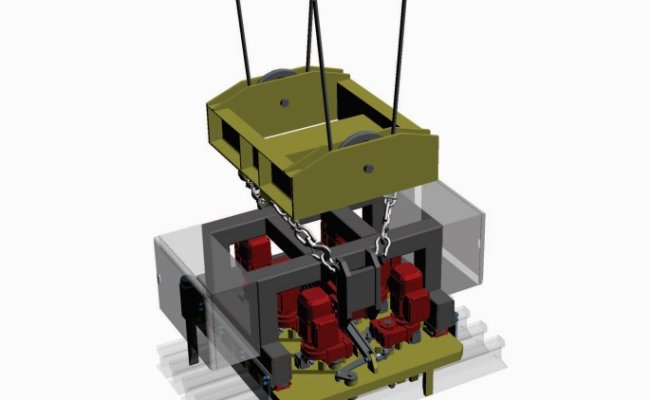

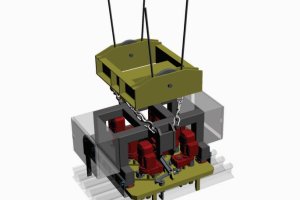

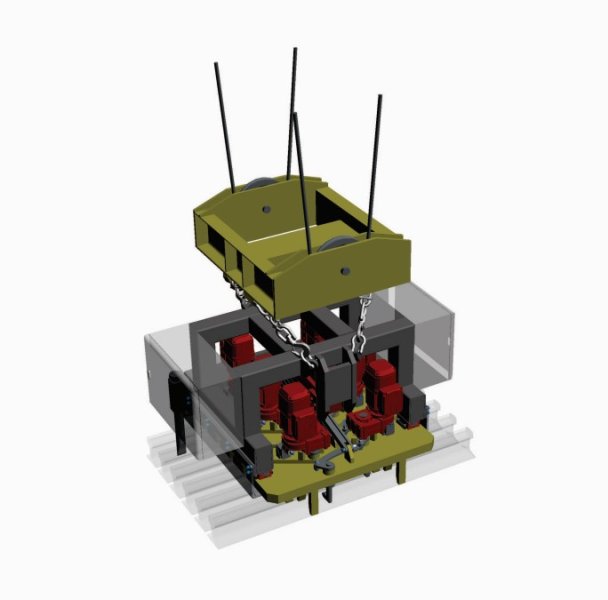

- inverter-controlled drives – smooth speed regulation for crane travel, trolley movement, and hoisting,

- remote (radio) control,

- optical and acoustic signaling,

- integrated communication system between the crane and traction power control system,

- signal exchange via potential-free contacts – ensuring compatibility and operational safety,

- safety logic based on PLC controllers – monitoring power status, parking, and hoist position,

- ready for integration with the superior Depot Management System (DMS).

User benefits:

- enhanced operational safety through precise synchronization of crane movements and traction system status,

- collision-free system interaction – track power is enabled only when crane status is confirmed safe,

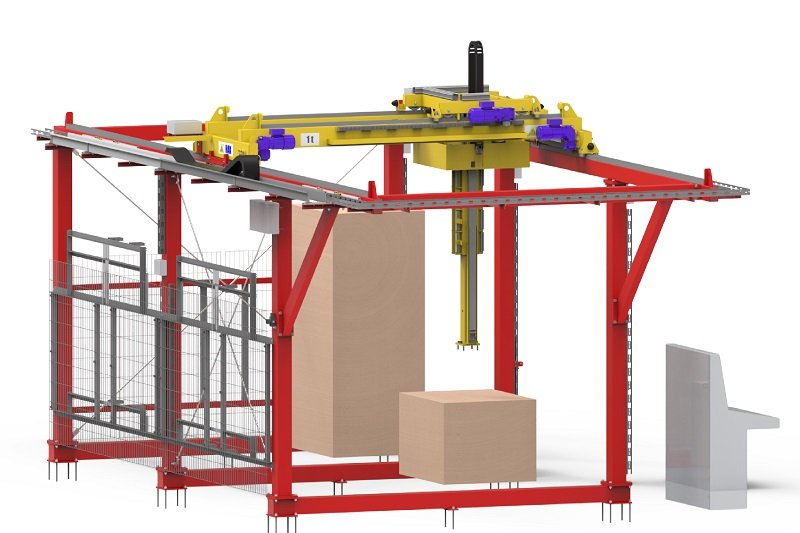

- automated equipment control – reduced operator intervention,

- reduced risk of errors and downtime – real-time system response to status changes,

- scalable architecture – open system design ready for future upgrades and integrations.

Applications:

- tram and railway depots,

- rail transport infrastructure facilities,

- areas requiring coordination between crane systems and electrical infrastructure,

- shared operational zones for lifting equipment and high-voltage power installations.