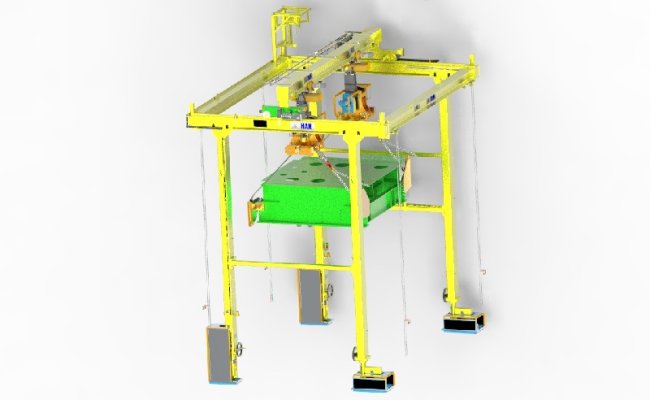

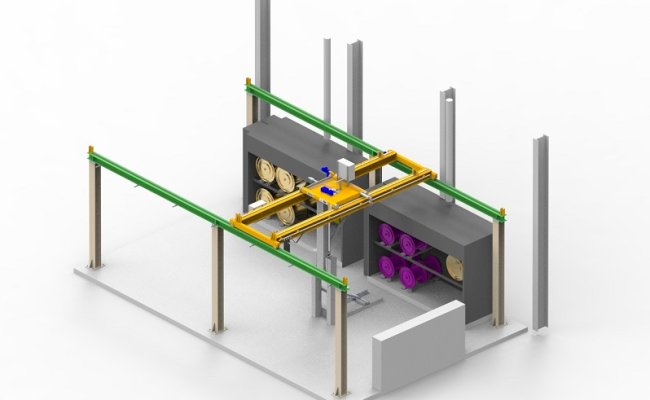

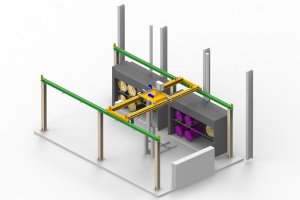

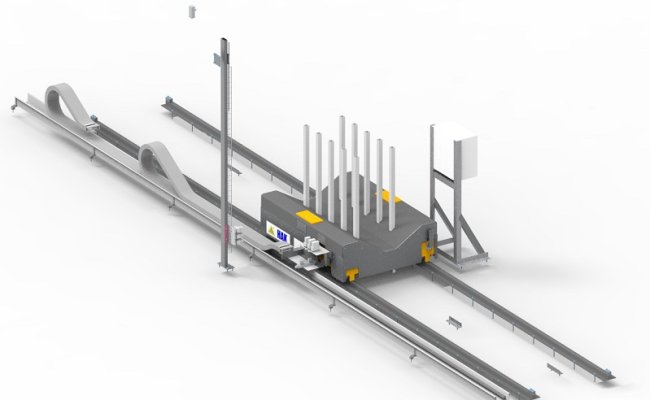

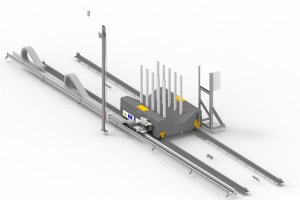

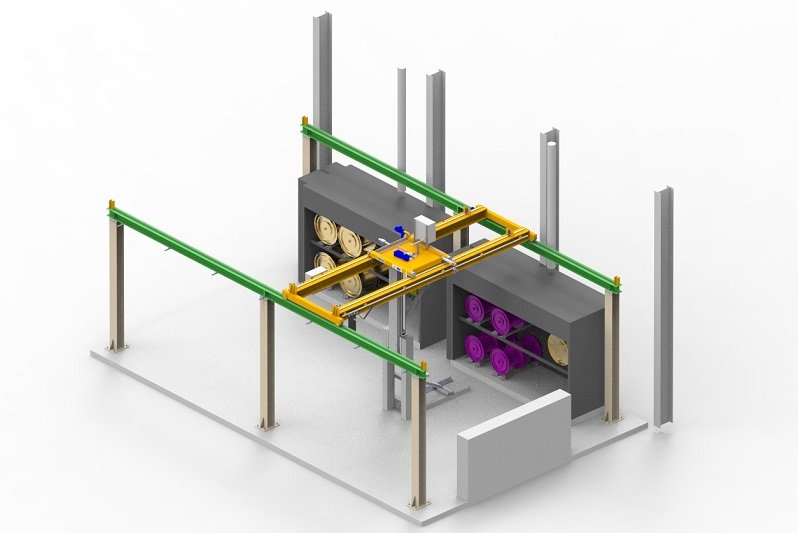

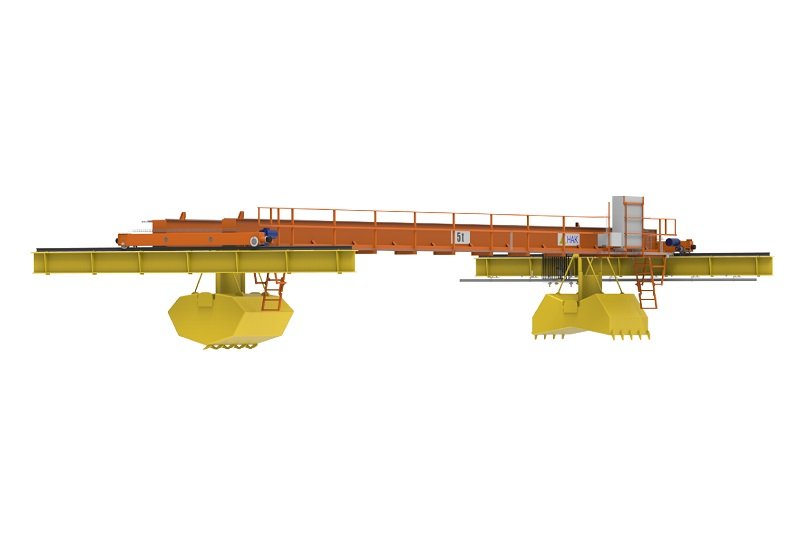

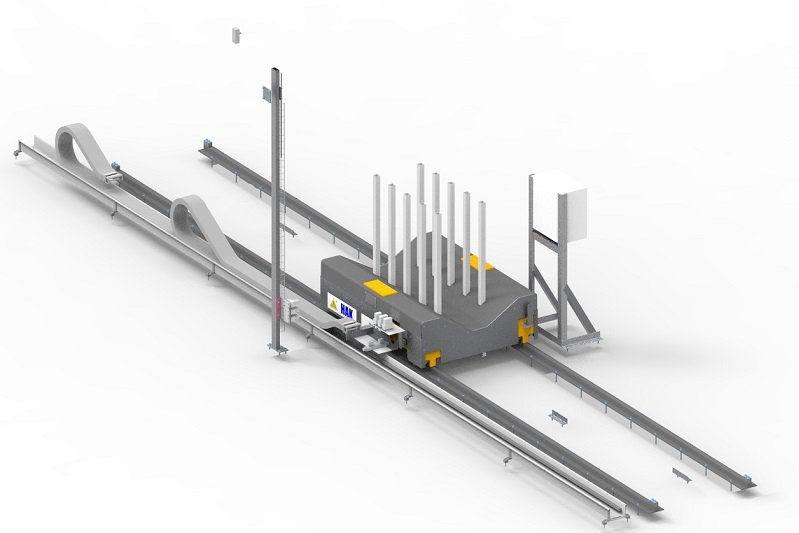

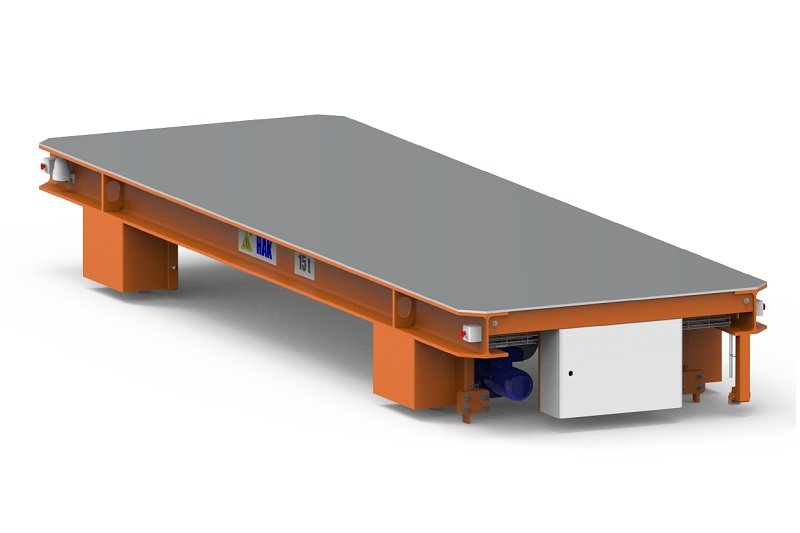

CRANE SYSTEM FOR CONTAINER TRANSPORT

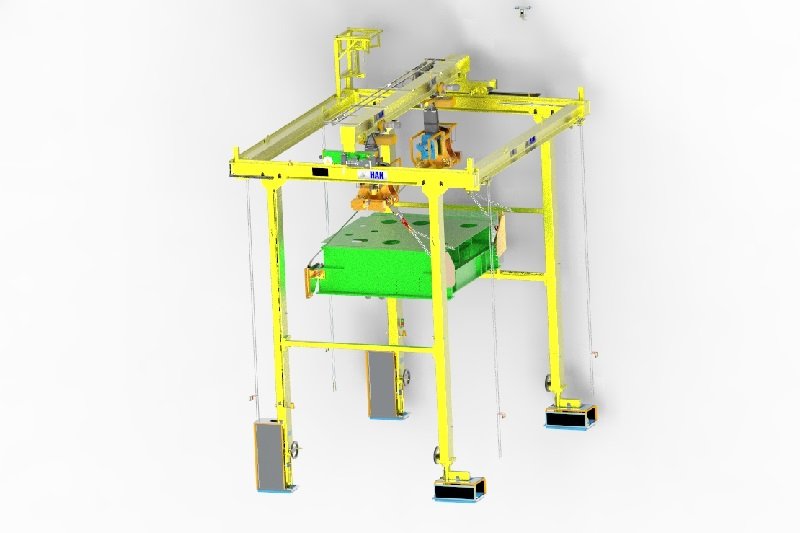

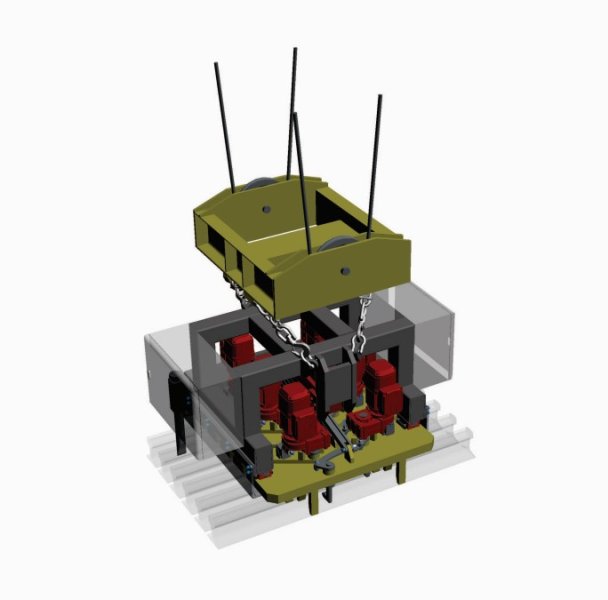

An advanced crane system designed for safe, precise, and efficient container handling. The system consists of two pillar-mounted cranes with a lifting capacity of 10 tons, equipped with grabs for container transport, and one pillar-mounted crane with a capacity of 6,5 tons, operating in an automated mode. Thanks to innovative solutions, this system streamlines and automates transport operations, significantly improving efficiency and safety.

FEATURES OF THE CONTAINER TRANSPORT SYSTEM

The implemented control solutions provide the operator with full control over crane movement in three directions: bridge travel, trolley travel, and load lifting/lowering. The cranes move smoothly and accurately, ensuring high precision and minimizing operational errors, which is crucial in high-duty industrial environments.

- each crane in the system is equipped with an advanced radio control system, allowing the operator to manage all functions with high precision,

- the radio transmitter, featuring rotary encoders, enables precise positioning of the crane in the required working position,

- limit switches and coded rail sensors ensure accurate monitoring and positioning of the crane, guaranteeing safe and precise operation,

- the crane automatically moves to the programmed position and stops precisely when reaching the exact X, Y, and Z coordinates,

- each storage location in the facility is clearly marked, facilitating fast and efficient transport operations for the operator.

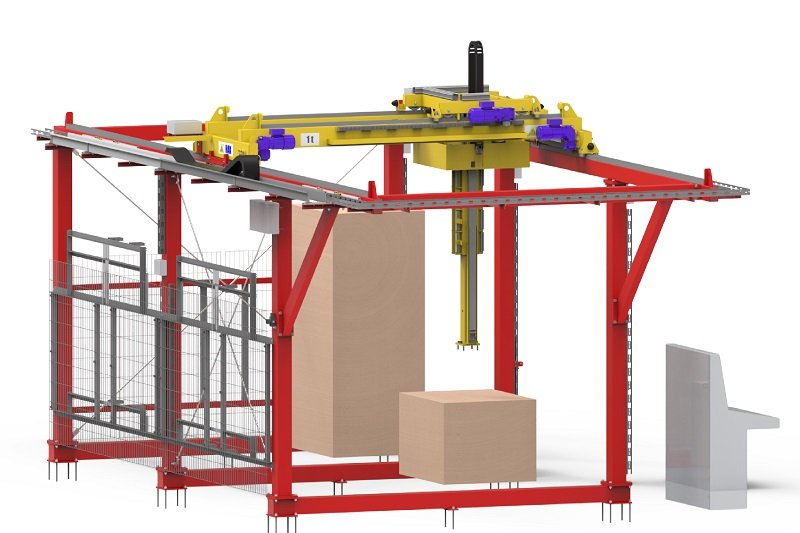

OPERATING MODES – AUTOMATION & SAFETY

The system features three working modes, ensuring both high efficiency and maximum safety. The operator can intervene in emergency situations, preventing potential accidents. The cranes are equipped with safety systems that immediately stop the operation in case of obstacles or other hazards, protecting personnel and equipment:

- automatic mode – The cranes execute pre-programmed tasks independently, minimizing operator intervention,

- semi-automatic mode – The operator can manually set the crane’s position while the system automatically stops when reaching the programmed coordinates,

- manual mode – Ensures maximum flexibility for handling complex operations.

BENEFITS OF THE SYSTEM

The use of a modern automated crane system provides numerous advantages, including:

- increased efficiency – automation and precise control shorten load transport times, accelerating workflow,

- enhanced safety – the safety systems and operator intervention capabilities ensure full protection of personnel and equipment,

- flexibility – multiple operating modes allow easy adaptation to changing production needs,

- precision execution – advanced sensors and coded rail systems ensure high accuracy, reducing the risk of errors,

- contamination protection – the cranes are designed to minimize exposure to contaminants such as zinc, iron, or lead, ensuring a safe and hygienic working environment.

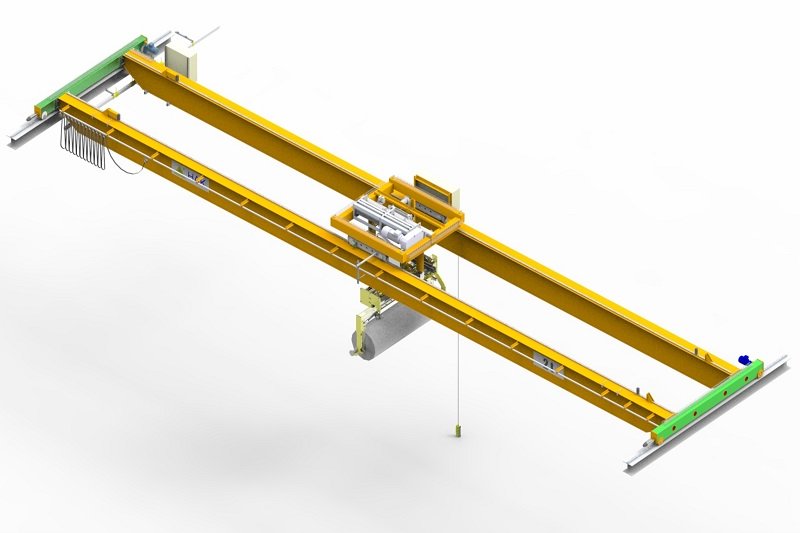

TECHNICAL DATA – PILLAR-MOUNTED CRANE Q=6,5T

crane lifting capacity: 6,5 t

hook operating range: 3800 mm

lifting height: 8 m

duty classification: A4

power supply voltage: 3 x 400V/50Hz

bridge travel speed: 40/10 m/min (inverter)

trolley travel speed: 20/5 m/min (inverter)

lifting speed: 4/1 m/min (inverter)

column rotation speed: 0.8 rpm

track length: 75 m

power supply type: conductor bar along the track

runway rail material: stainless steel

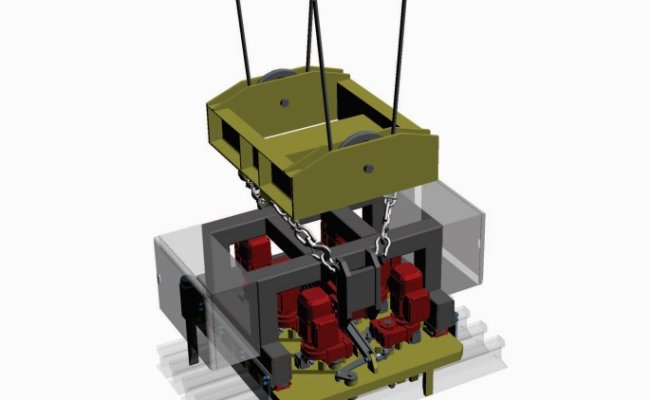

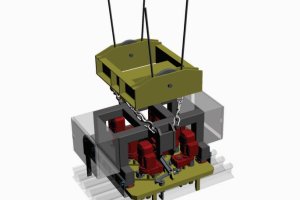

container grab lifting capacity: 6,5 t

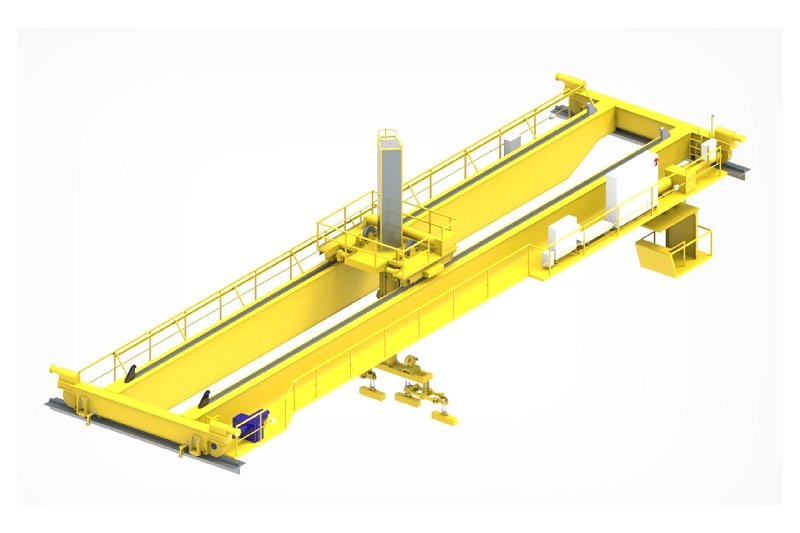

TECHNICAL DATA – PILLAR-MOUNTED CRANE Q=10,0T

crane lifting capacity: 10 t

crane span: 10900 mm

duty classification: M7

power supply voltage: 3 x 400V/50Hz

bridge travel speed: 40/10 m/min (inverter)

trolley travel speed: 20/5 m/min (inverter)

lifting speed: 8/1 m/min (inverter)

column rotation speed: 0,8 rpm

power supply type: conductor bar along the track / INOX festoon cable

power supply length: 50 m

container grab lifting capacity: 6,5 t