Automatic Wagon Box Transport System

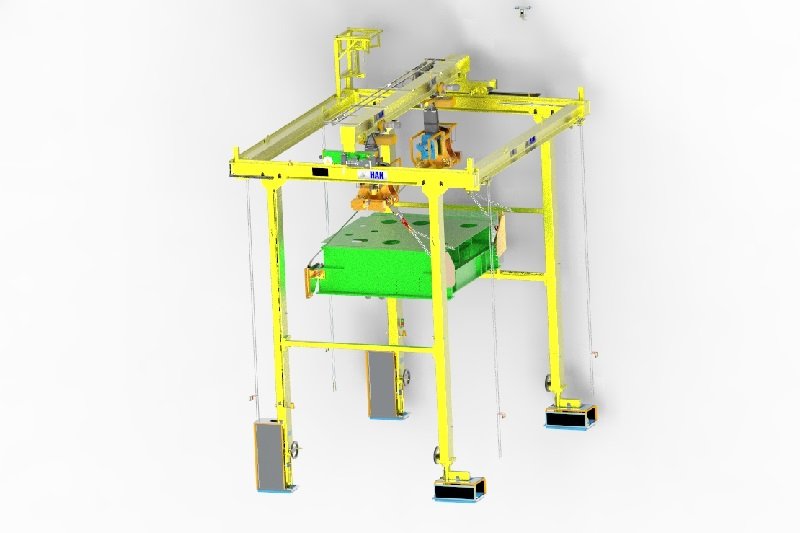

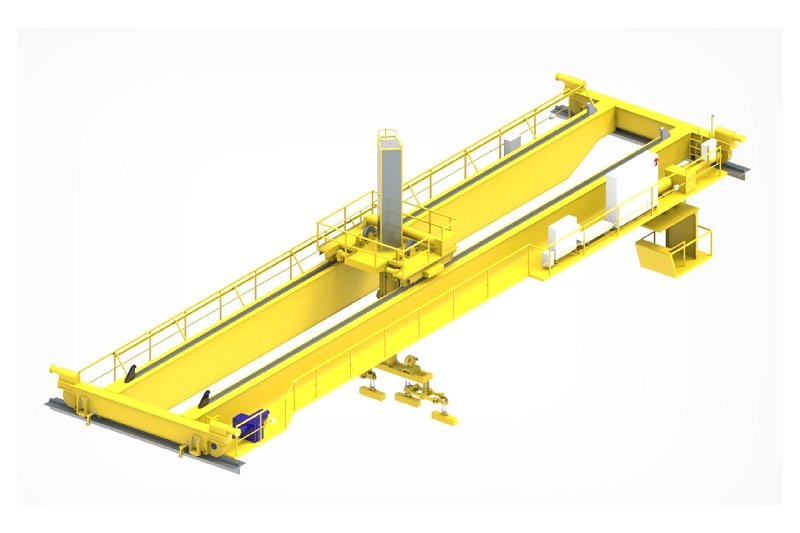

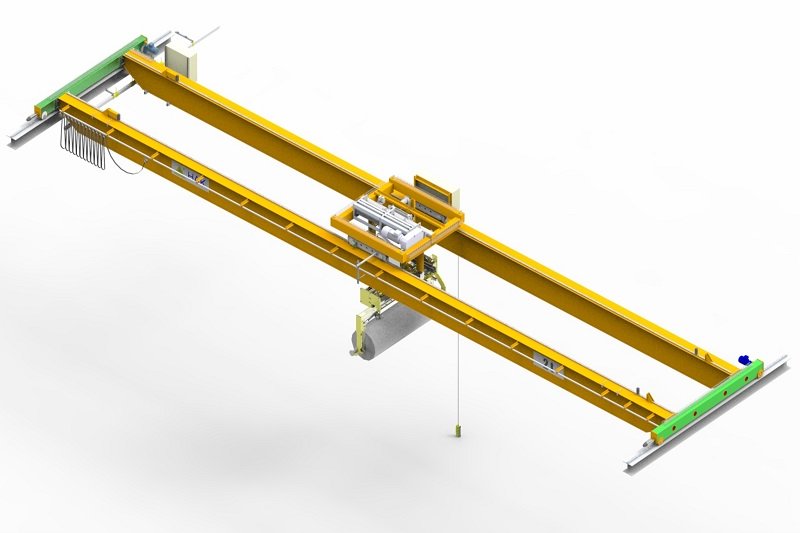

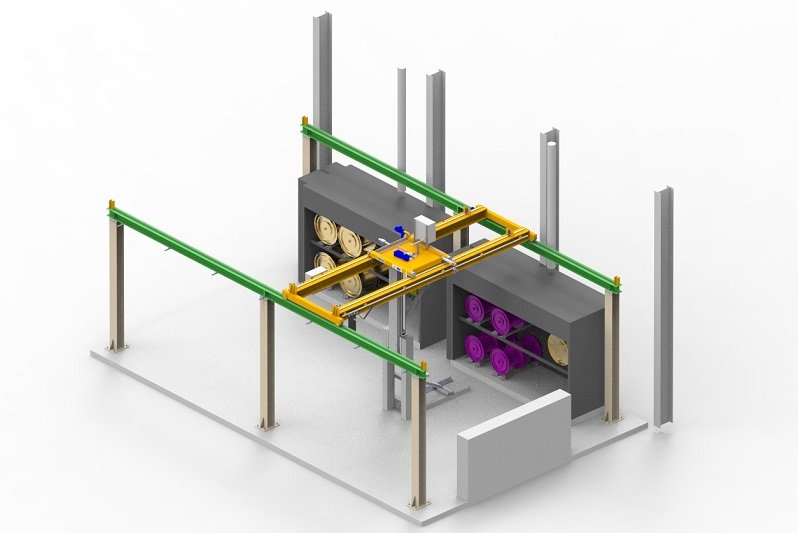

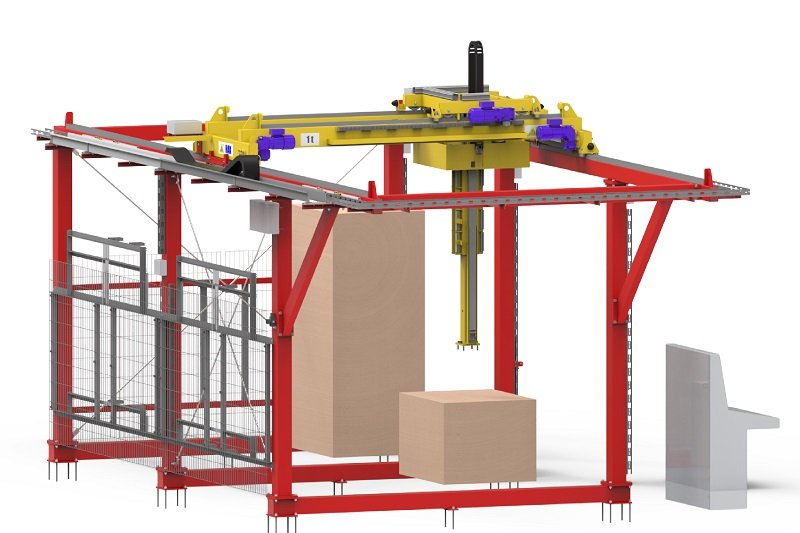

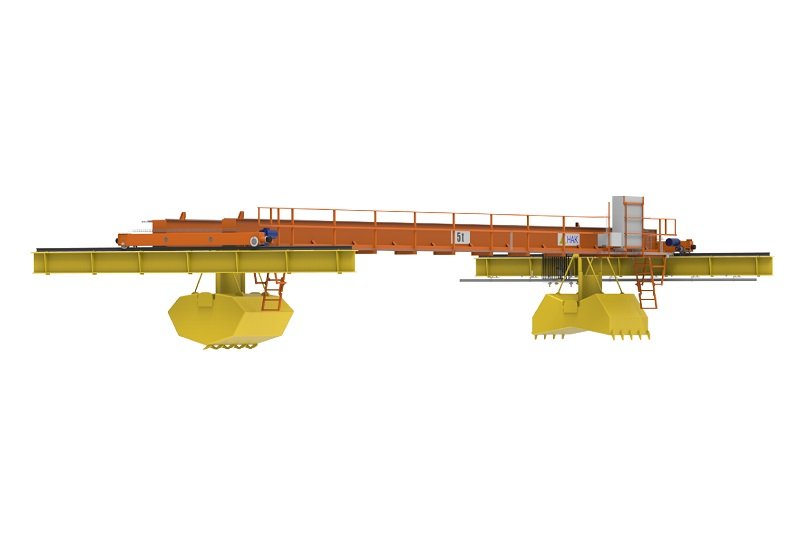

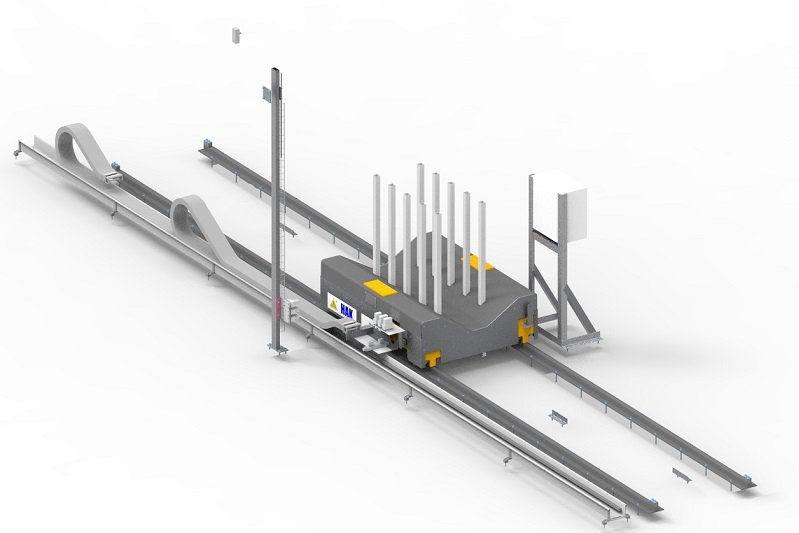

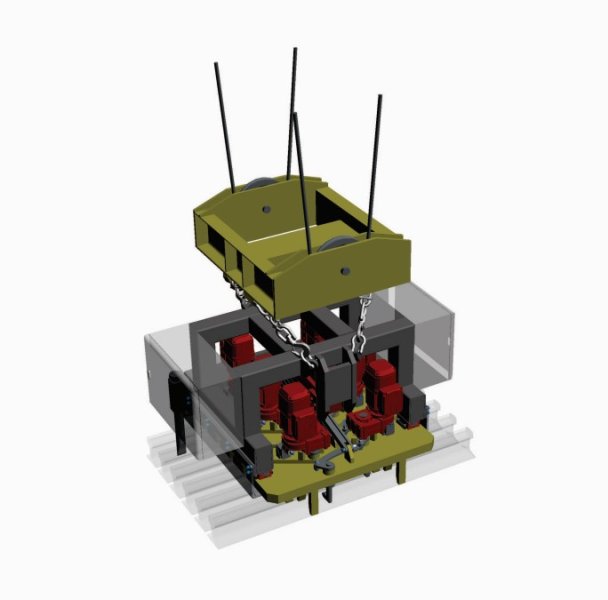

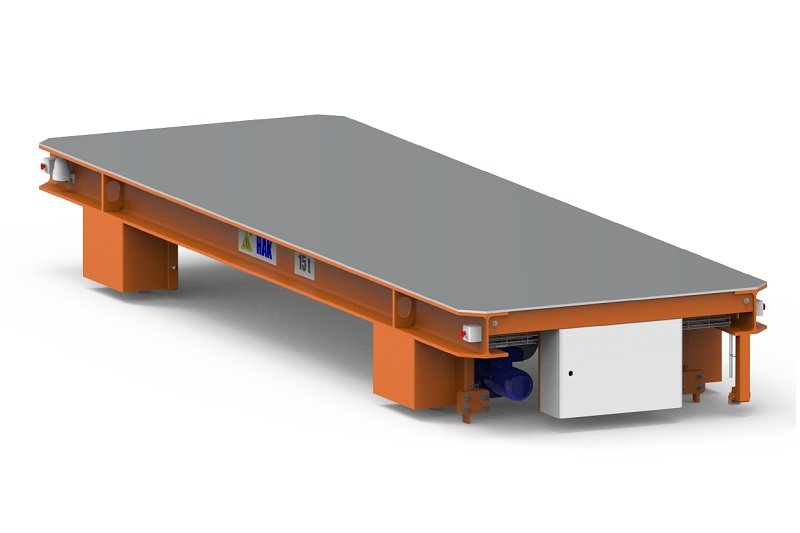

An automated rail shifter system designed and manufactured for transporting railway wagon boxes during processing and assembly.

Got questions?

Contact us

Got questions?

Contact us

An automated rail shifter system designed and manufactured for transporting railway wagon boxes during processing and assembly.

| Parameters | Value |

| Device Parameters (dimensions, load capacity, control, power supply, working speeds) |

As required |

| Catalog number | WR191158 |

An automated rail shifter system designed and manufactured for transporting railway wagon boxes during processing and assembly.

A rail shifter is a device used to move rail vehicles between parallel tracks, applied in locations where the construction of railway switches is not feasible, such as in repair shops and locomotive sheds, coal and ore sorting facilities, or at loading ramps. This type of solution is also used as equipment for technological lines producing rail vehicle components, facilitating the movement of wagon boxes and locomotives between different stages of processing and assembly.

FEATURES OF THE AUTOMATIC WAGON BOX TRANSPORT SYSTEM

BENEFITS OF USING THE SYSTEM

APPLICATION

Send an offer request

See also

Headquarters

Web store

8F Jerzmanowska street, 54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00

Headquarters

Web store

8F Jerzmanowska street,

54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00