Automatic System for Alternative Fuel Storage

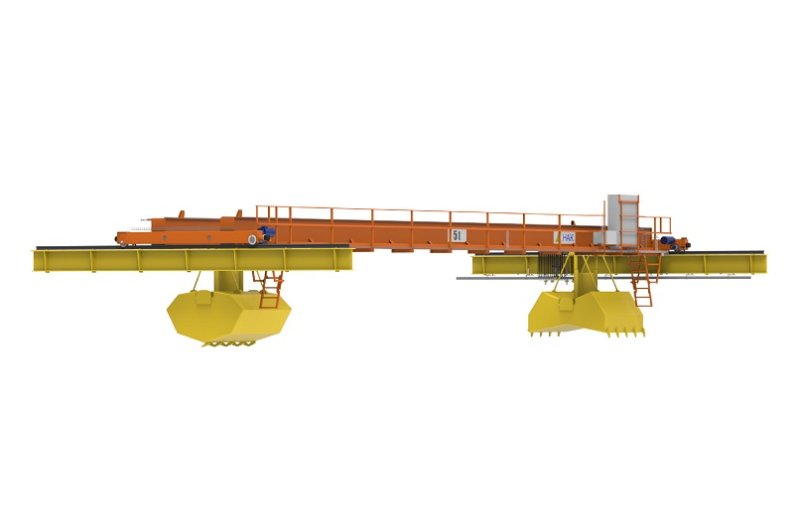

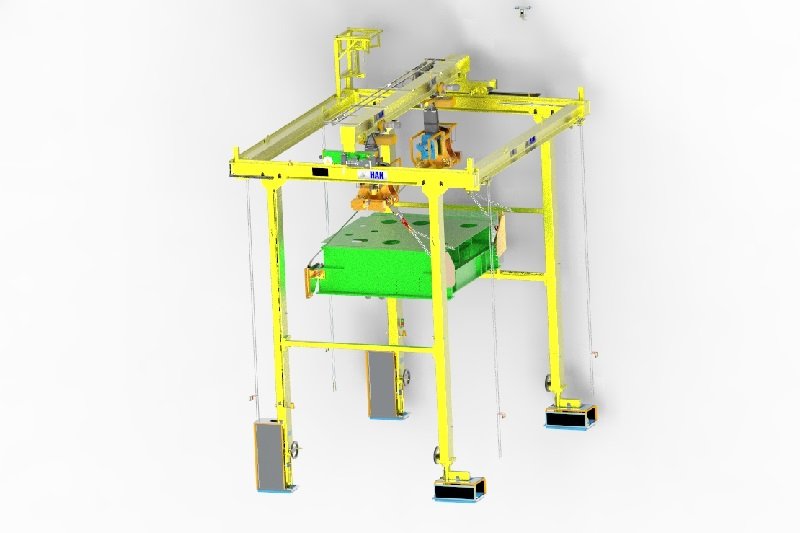

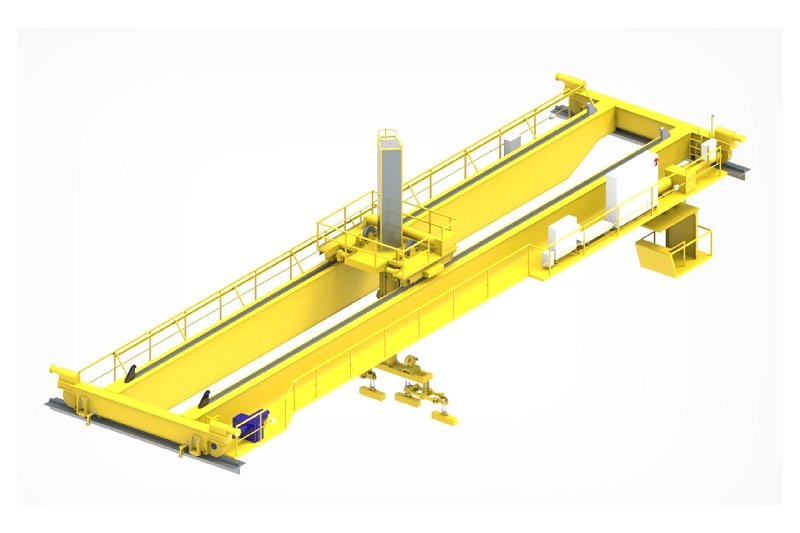

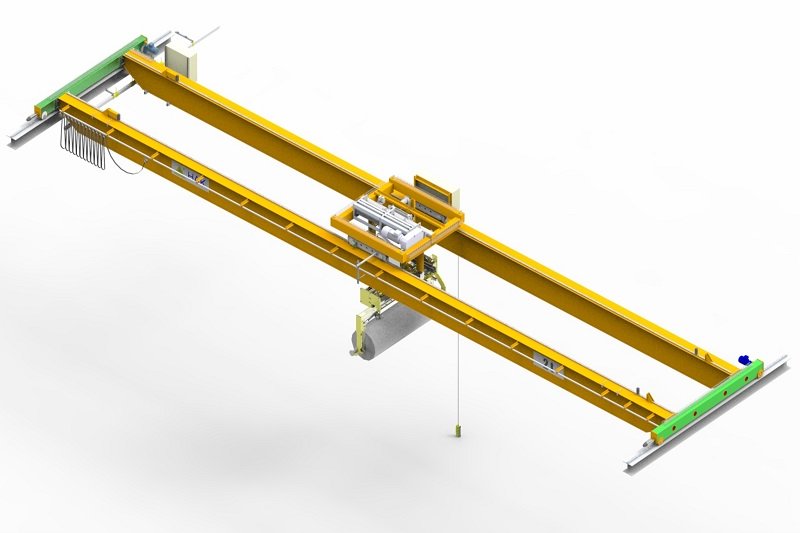

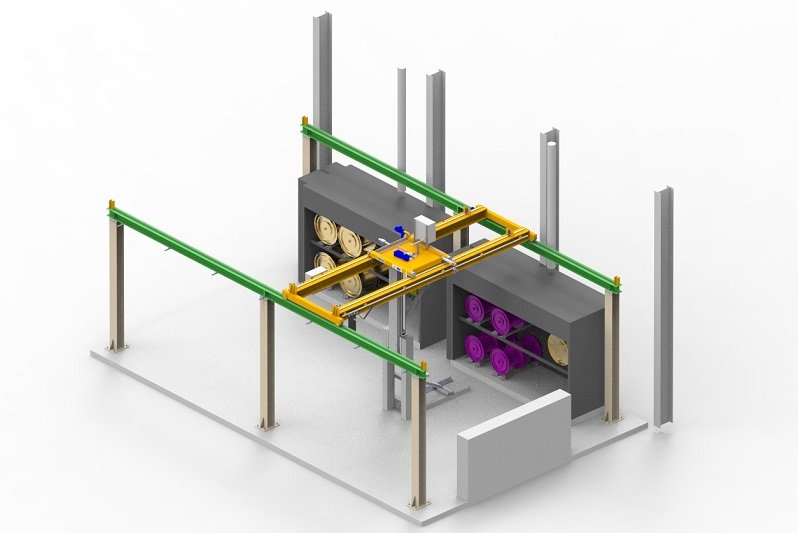

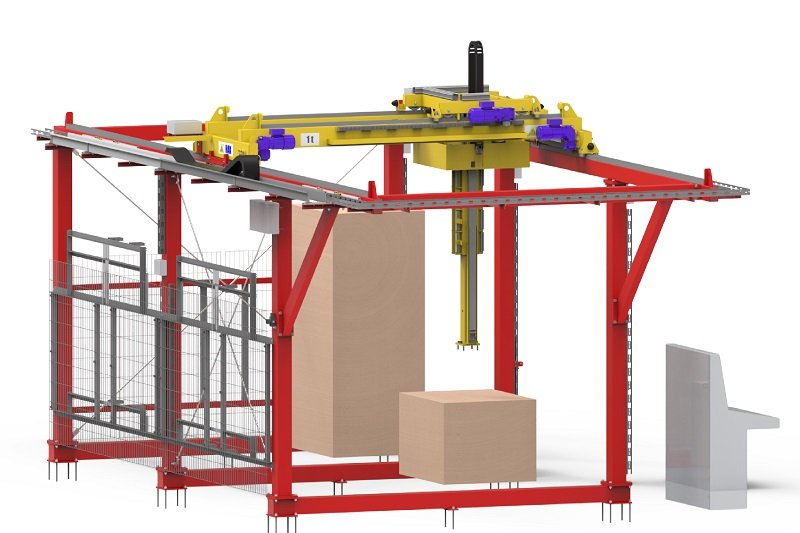

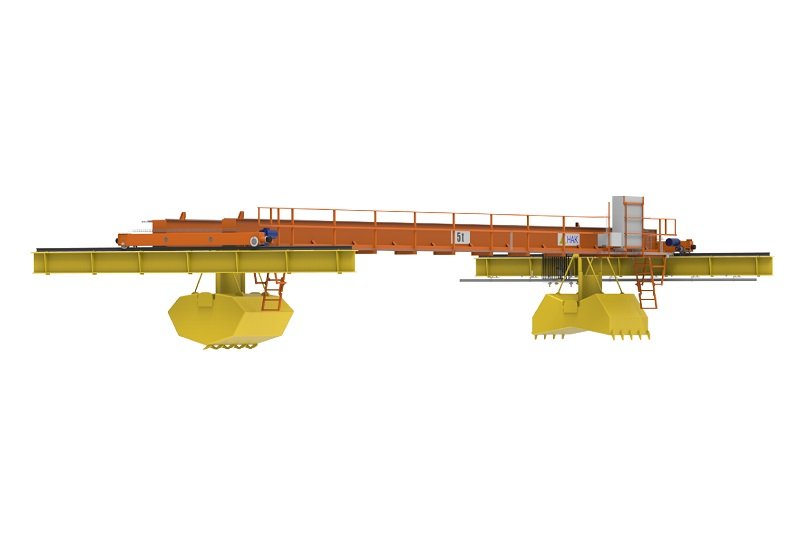

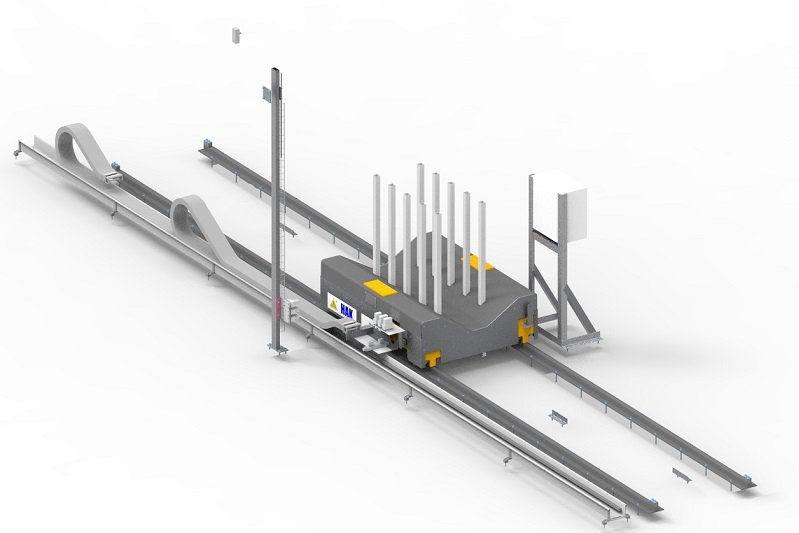

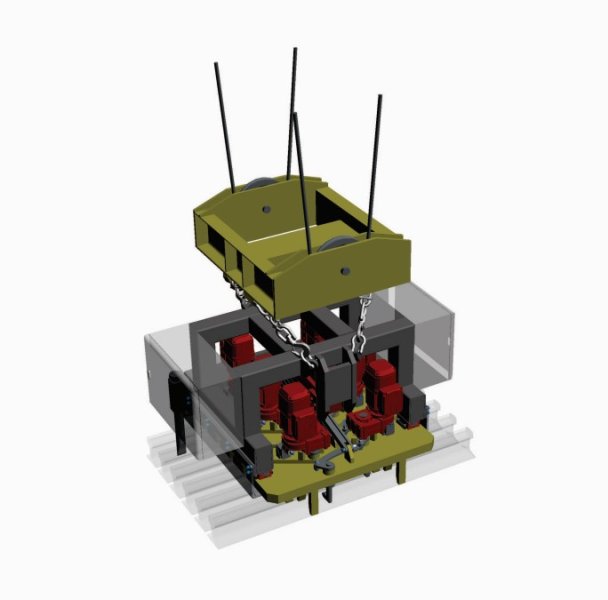

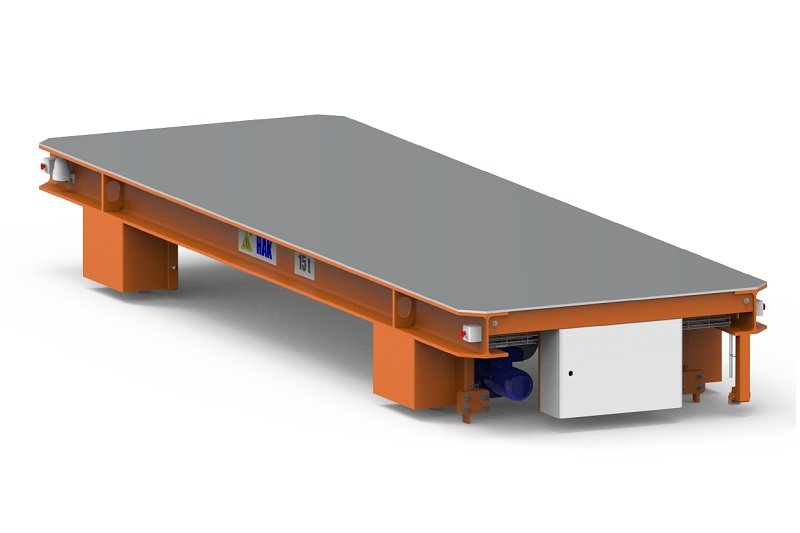

An automated system consisting of two devices equipped with grabs has been designed for the handling and retrieval of material in an alternative fuel storage facility.

Got questions?

Contact us

Got questions?

Contact us

An automated system consisting of two devices equipped with grabs has been designed for the handling and retrieval of material in an alternative fuel storage facility.

| Parameters | Value |

| Device Parameters (dimensions, load capacity, control, power supply, working speeds) |

as required |

| Catalog number | NS120913 |

An automated system consisting of two devices equipped with grabs has been designed for the handling and retrieval of material in an alternative fuel storage facility.

The storage of problematic materials—those harmful to health—requires a solution that minimizes direct human involvement in device management. For an alternative fuel storage facility, particularly for dusty materials, a system of two cranes equipped with grabs has been developed. This system allows for the handling and movement of material within a closed, automatically controlled system managed externally.

FEATURES OF THE AUTOMATIC SYSTEM FOR ALTERNATIVE FUEL STORAGE

BENEFITS OF USING THE SYSTEM

APPLICATION

Send an offer request

See also

Headquarters

Web store

8F Jerzmanowska street, 54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00

Headquarters

Web store

8F Jerzmanowska street,

54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00