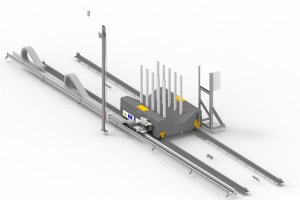

Automatic steel elements transport system

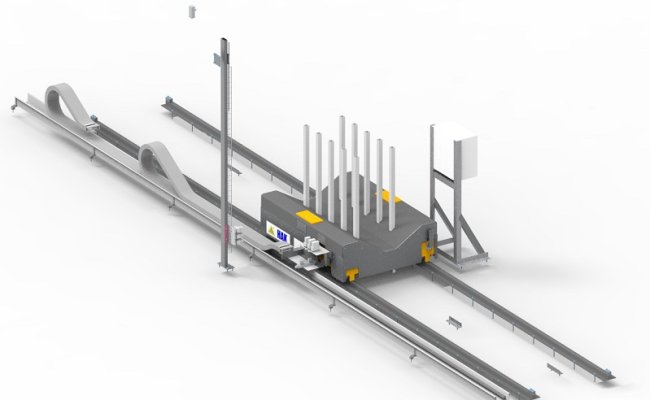

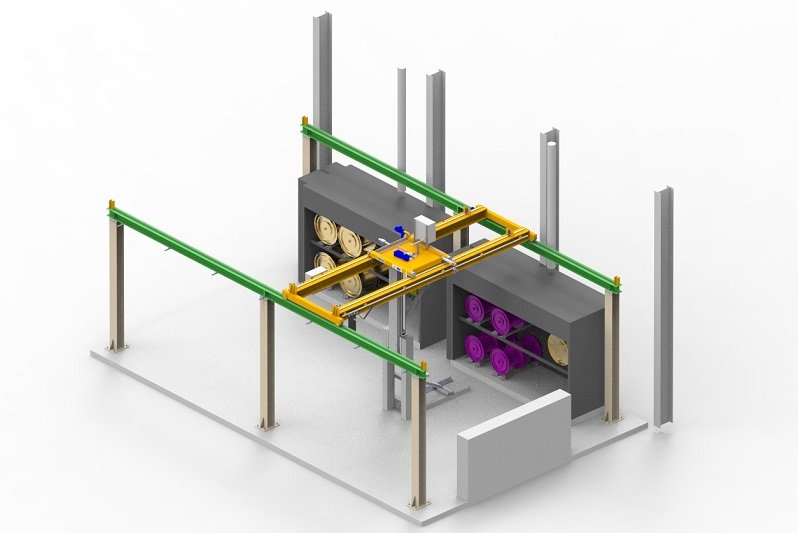

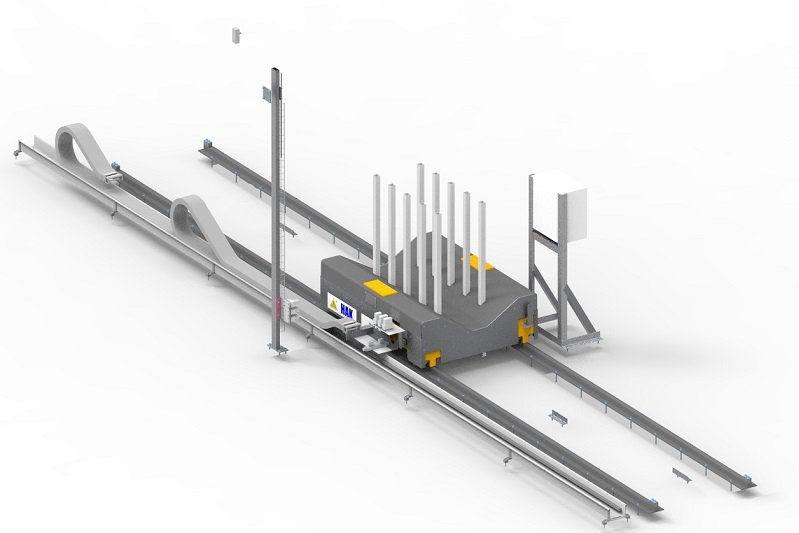

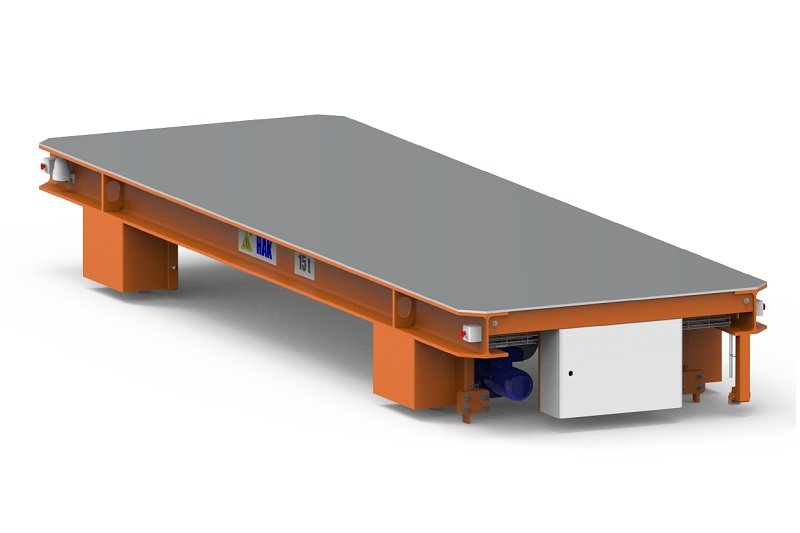

The system, consisting of two devices, is designed for the transportation of sheet piles and longitudinal steel elements, ensuring safe and efficient operation in processes that require the handling of long steel elements.

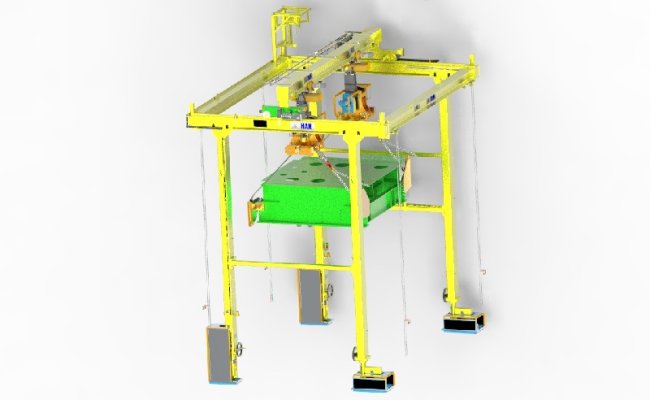

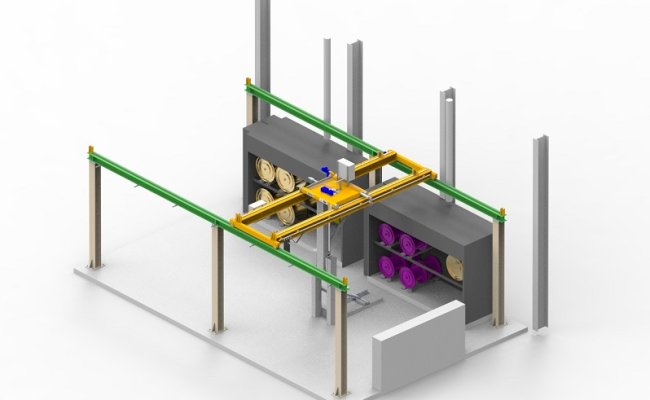

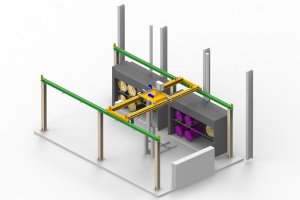

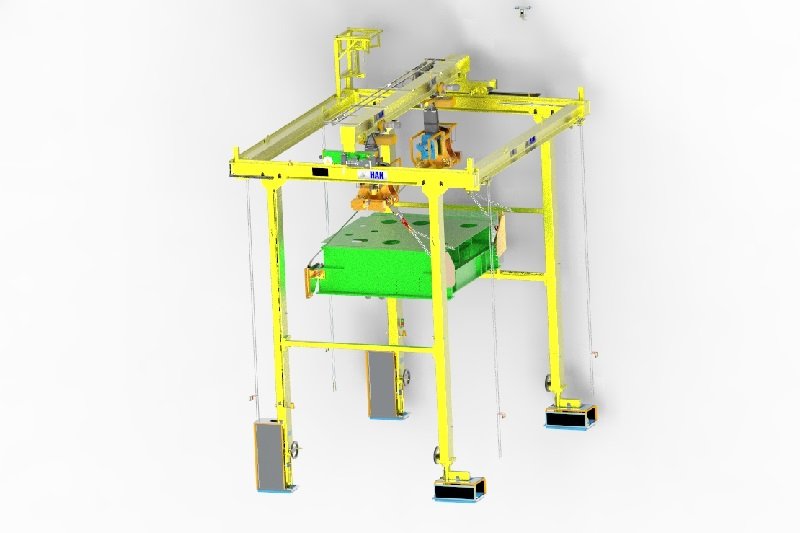

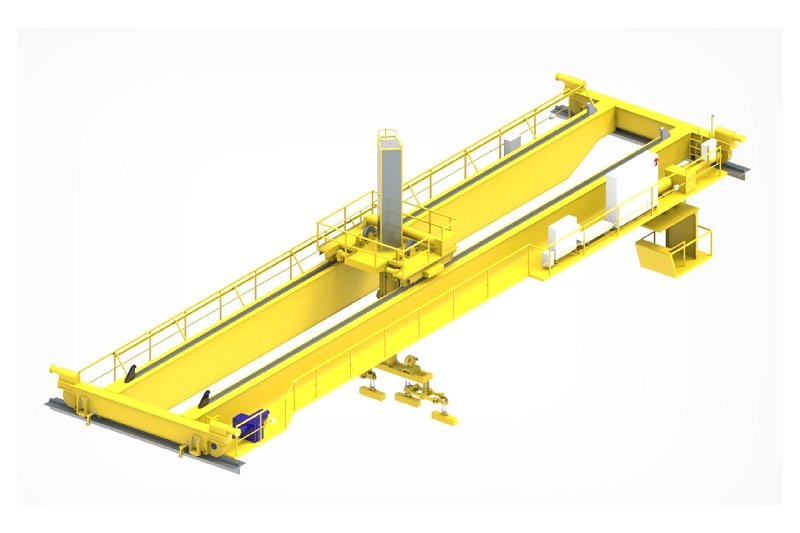

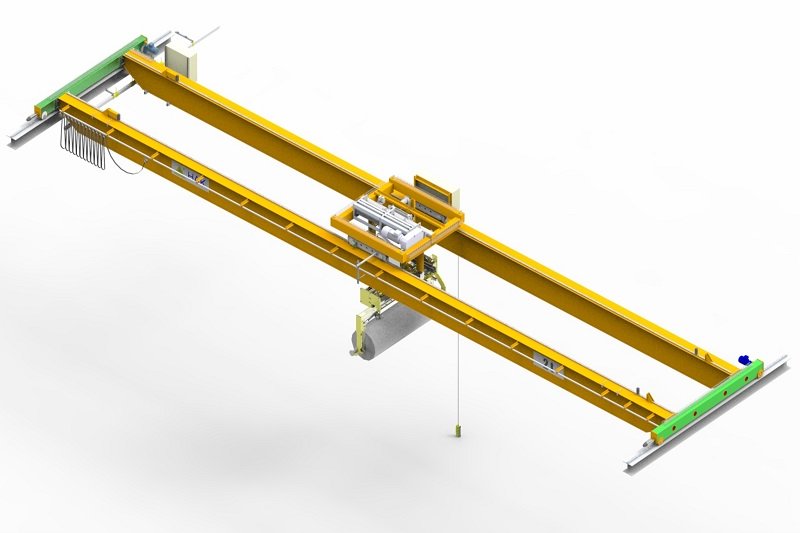

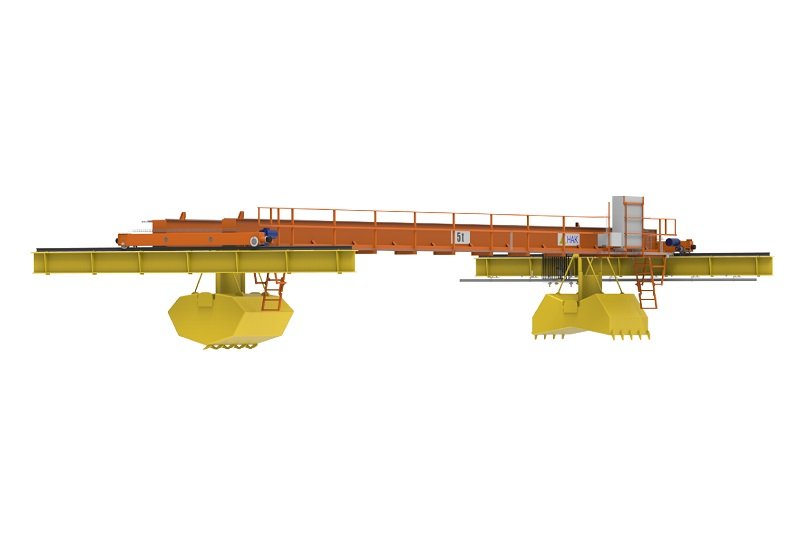

Transporting sheet piles, which are long steel elements used for creating waterproof barriers, requires a solution that is not only efficient but also highly reliable. This process led to the development of a specialized solution based on the tandem operation of two overhead cranes equipped with column hoists and electromagnetic grabs mounted on pivoting chains. The operation of the devices is coordinated through automation and mechanical coupling, allowing them to work separately or in tandem, enabling the transport of sheet pile sections up to 30 meters in length.

FEATURES OF THE AUTOMATIC SHEET PILE TRANSPORT SYSTEM

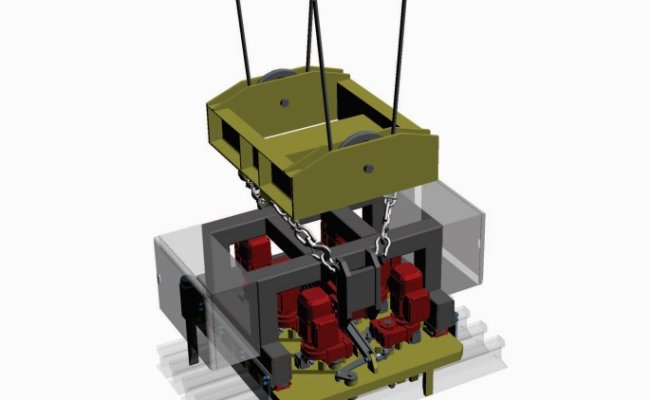

- tandem configuration – the system consists of two large-scale manipulators, derived from the concept of column overhead cranes, operating in a tandem system,

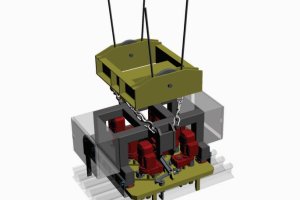

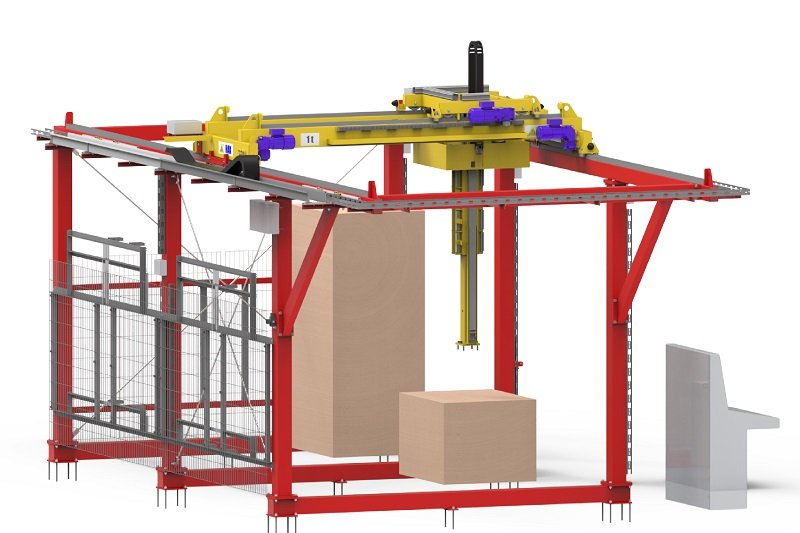

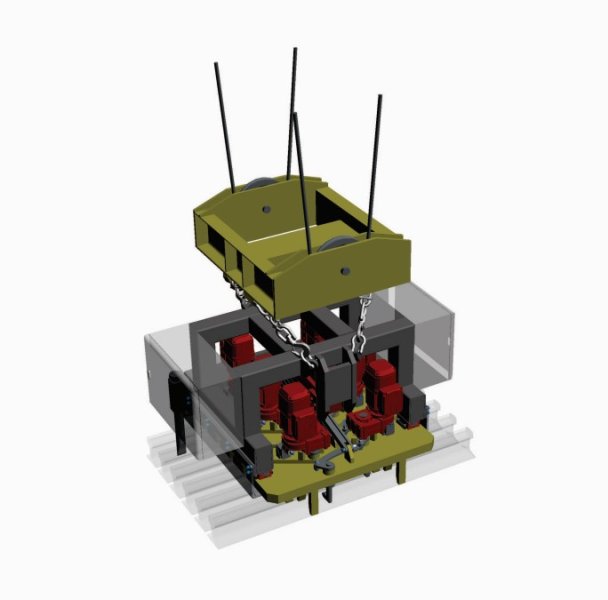

- flexible configuration – the columns of both manipulators are equipped with telescopic hoists, on which lifting beams with electromagnets are mounted on pivoting rotating chains,

- efficient and effective transport – the pivoting chains of the electromagnets allow for a single-line or dual-line configuration, depending on the number of transported sheet piles, enabling the transport of loads up to 6.5 tons and 30 meters in length,

- independent or tandem operation – precise operation is ensured by mechanical coupling and an automatic communication system between the devices,

- safety guarantee – the installation is equipped with a working area limit system,

- convenient control – system operation can be conducted autonomously, from the cabin, or remotely via a radio system,

- flexible transport capabilities – the system allows for the transport of individual sheet piles or paired piles, depending on operational needs,

- customizable configurations – the system can be designed in various size configurations to meet specific requirements.

BENEFITS OF USING THE SYSTEM

- increased efficiency in transporting long steel elements, either individually or in bundles,

- enhanced accuracy in handling sheet piles and other steel elements,

- process automation for handling single sheet piles or bundles,

- simplified installation based on dual-girder cranes,

- increased workplace safety through advanced automation and control systems.

APPLICATION

- transporting sheet piles, I-beams, metal strips, etc.,

- handling long-section metal elements, either individually or in bundles.