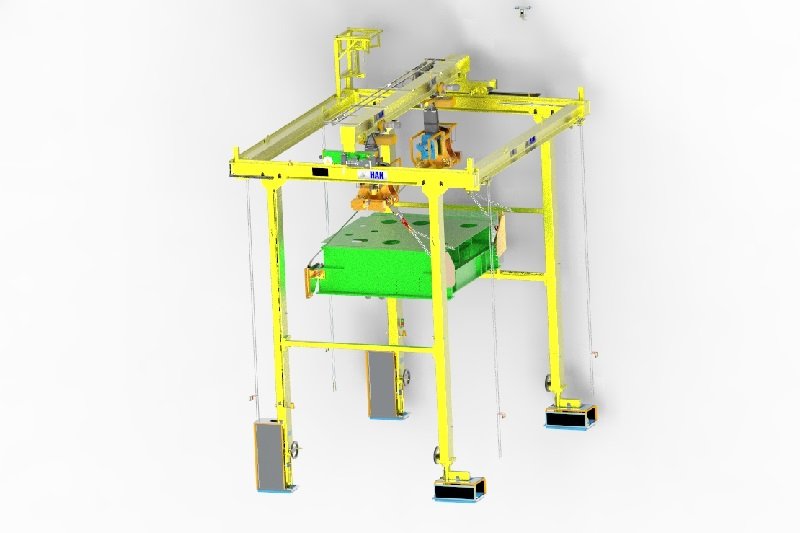

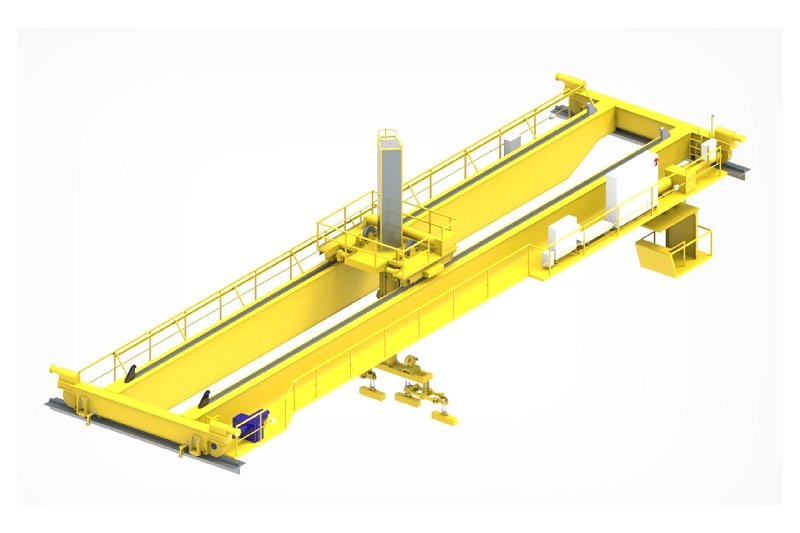

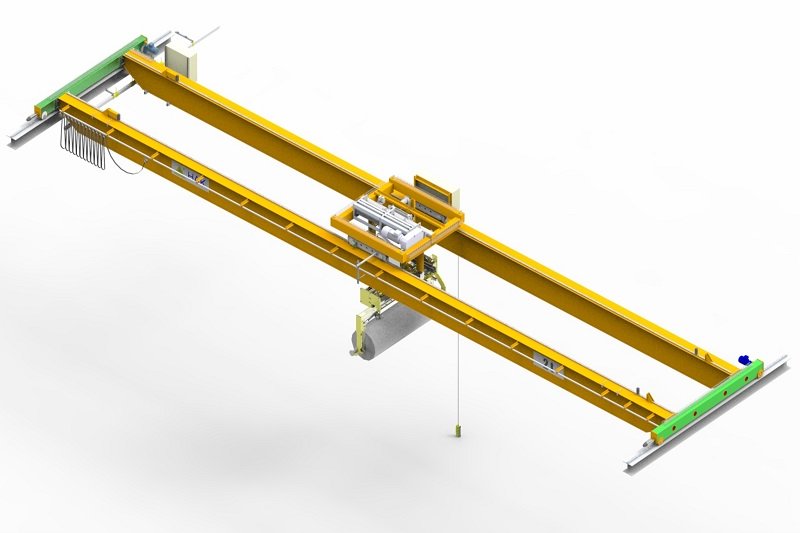

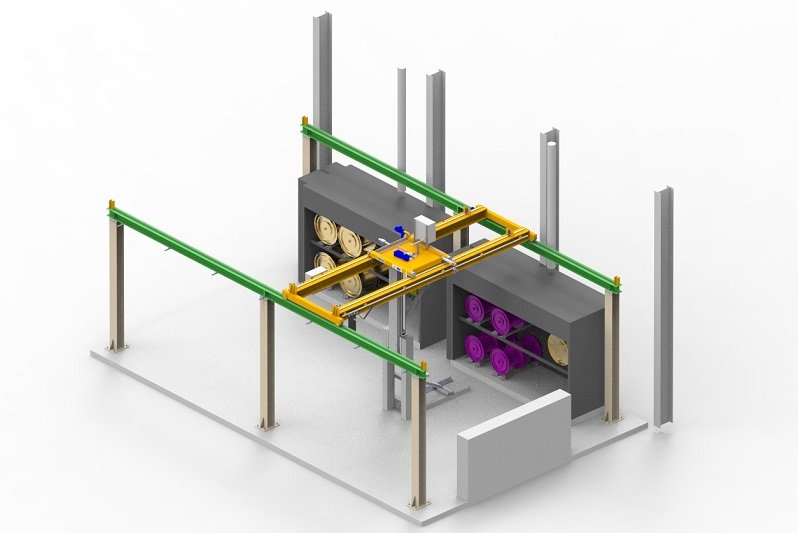

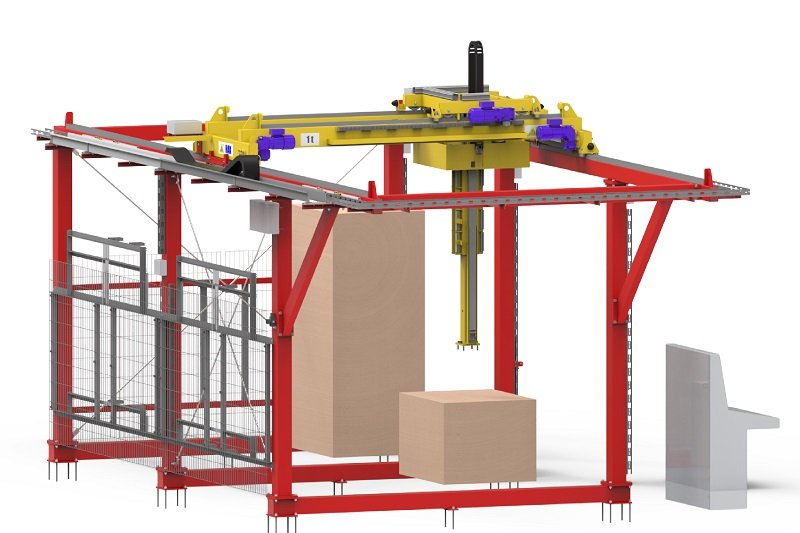

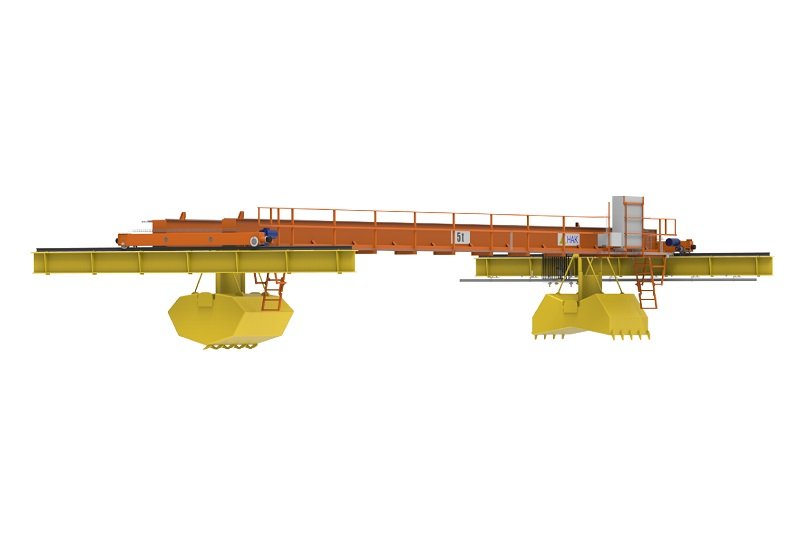

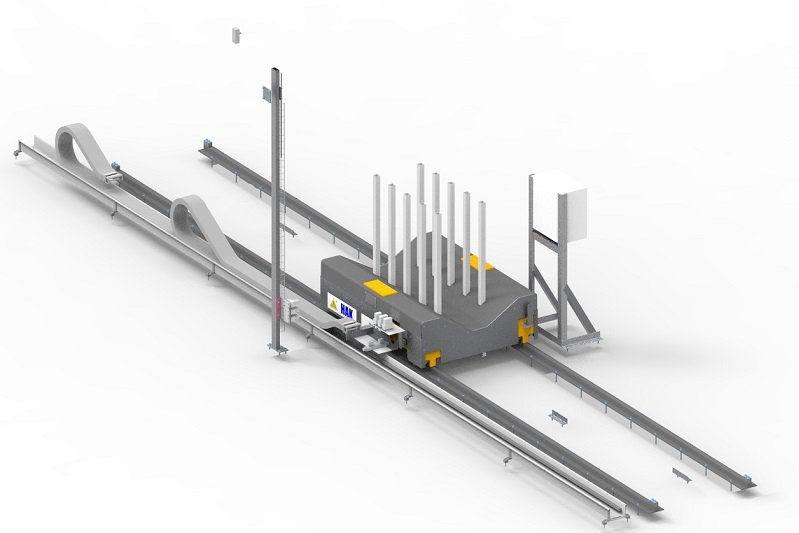

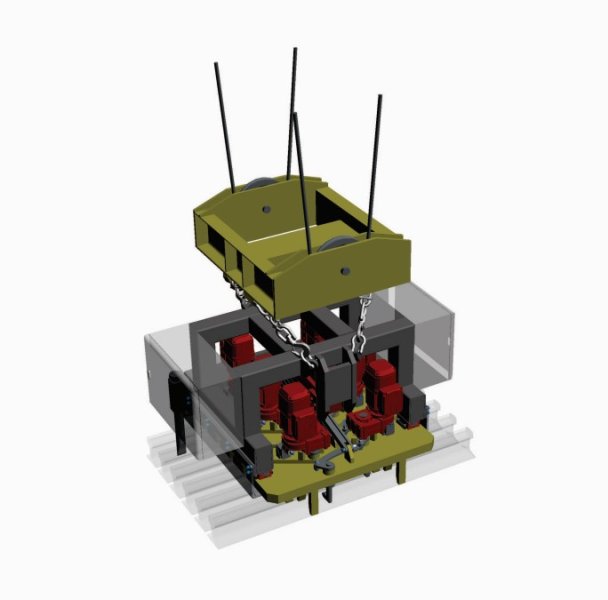

Automatic mould circulation and exchange system

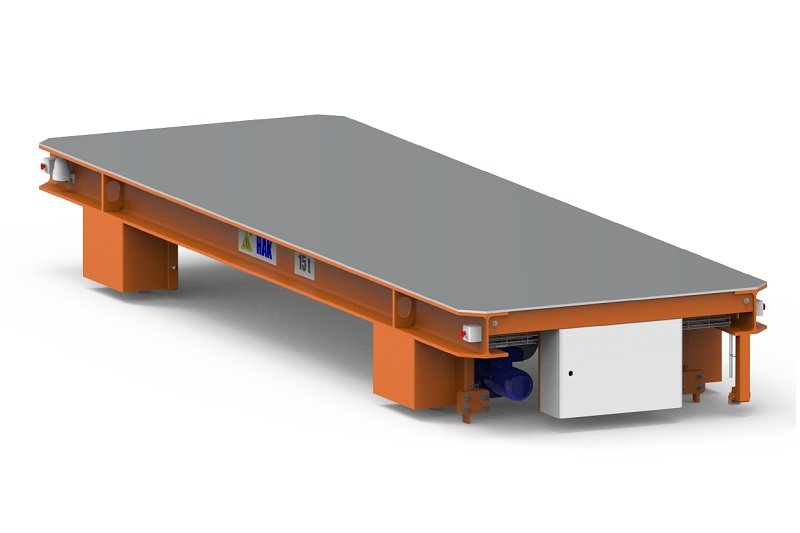

The transport system, together with the large mould storage, is designed to work in an automatic cycle in factories producing rubber products.

Got questions?

Contact us

Got questions?

Contact us

The transport system, together with the large mould storage, is designed to work in an automatic cycle in factories producing rubber products.

| Parameters | Value |

| Device Parameters (dimensions, load capacity, control, power supply, working speeds) |

as required |

| Catalog Number | GD134061 |

The transport system, together with the large mould storage, is designed to work in an automatic cycle in factories producing rubber products.

This transport system is an example of a solution created for modern warehouses and production lines. The role of the system is to deliver large, longitudinal moulds from storage to the press, and then to retrieve them from the press and return them to storage. Thanks to the applied components and technical solutions, the device is efficient, effective, and easy to maintain and operate.

FEATURES OF THE AUTOMATIC MOULD CIRCULATION AND EXCHANGE SYSTEM

BENEFITS OF USING THE SYSTEM

APPLICATION

Send an offer request

See also

Headquarters

Web store

8F Jerzmanowska street, 54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00

Headquarters

Web store

8F Jerzmanowska street,

54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00