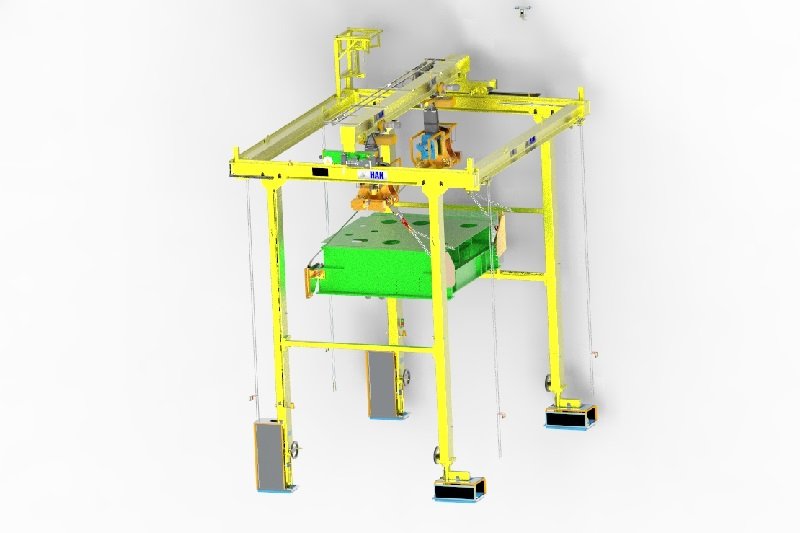

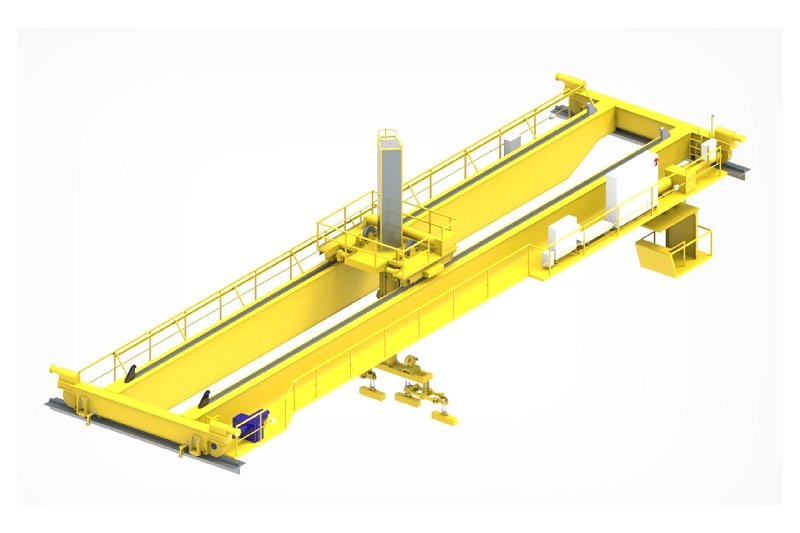

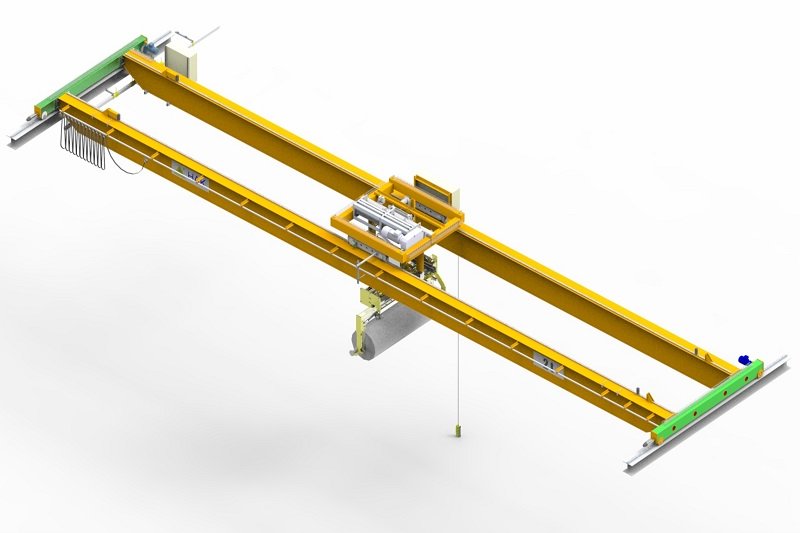

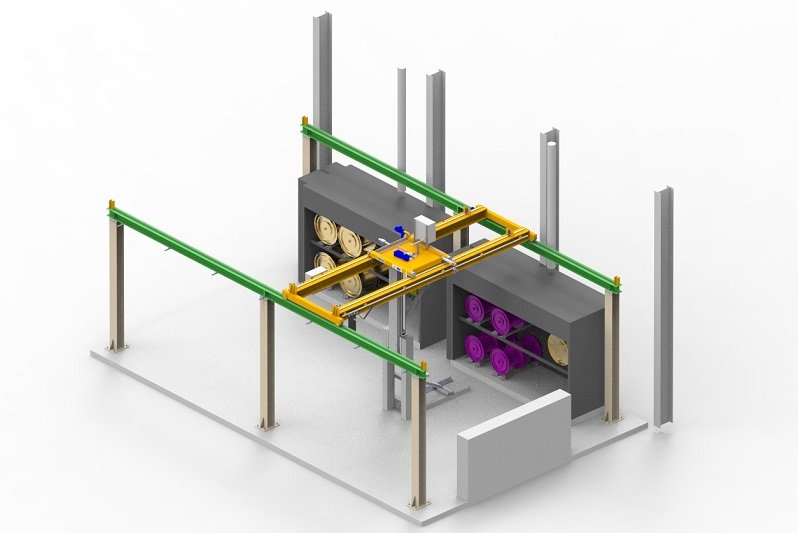

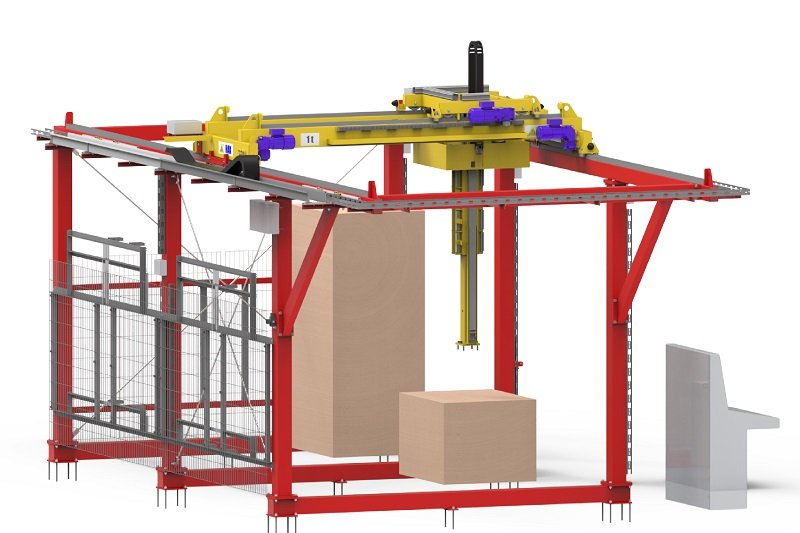

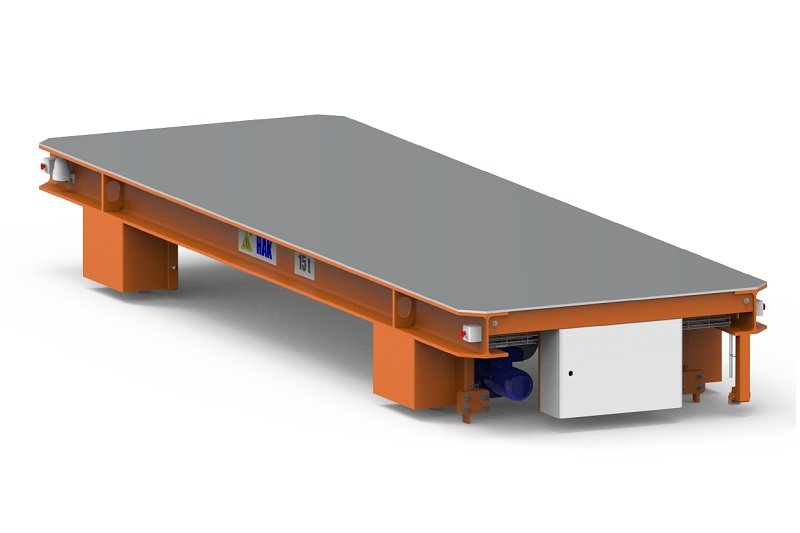

Automatic drum transport handling system

The device is designed for efficient, safe, and effective transport of loads such as shafts, bars, and drums in production and storage processes across various industries.

Got questions?

Contact us

Got questions?

Contact us

The device is designed for efficient, safe, and effective transport of loads such as shafts, bars, and drums in production and storage processes across various industries.

| Parameters | Value |

| Device Parameters (dimensions, load capacity, control, power supply, working speeds) |

as required |

| Dimensions | as required |

| Work speed | as required |

| Lifting height of the hoist | 5 000 - 6 000 mm |

| Catalog number | PL102919 |

The device is designed for efficient, safe, and effective transport of loads such as shafts, bars, and drums in production and storage processes across various industries.

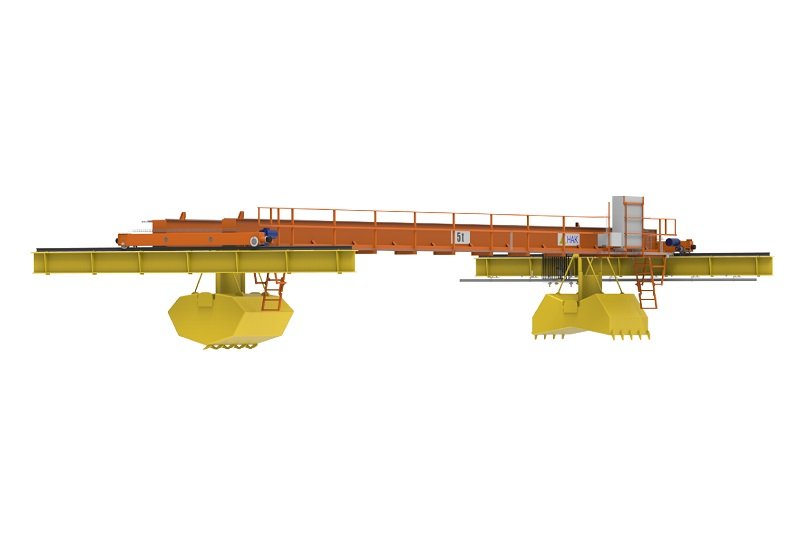

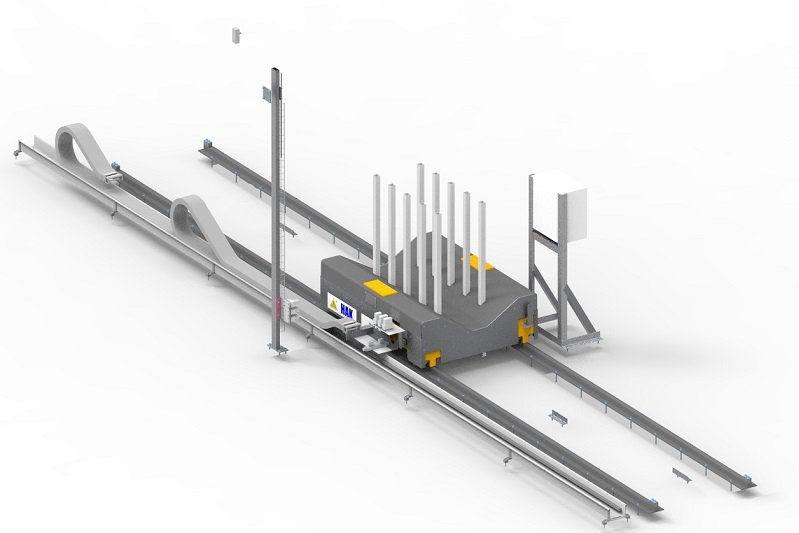

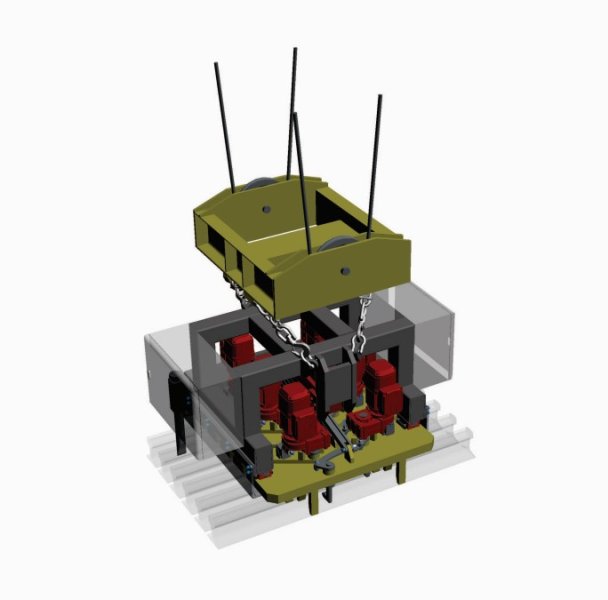

The drum transport manipulator is based on a dual-girder overhead crane design, equipped with a lifting beams mounted on rigid pivoting chains, allowing for stable lifting and lowering of the load. An additional enhancement is the semi-automatic operation system, which involves programming the device with specific movement sequences and stopping at precisely defined positions.

FEATURES OF THE AUTOMATIC DRUM TRANSPORT HANDLING SYSTEM

BENEFITS OF USING THE SYSTEM

APPLICATION

Send an offer request

See also

Headquarters

Web store

8F Jerzmanowska street, 54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00

Headquarters

Web store

8F Jerzmanowska street,

54-519 Wrocław

Open hours on weekdays:

07:00 - 16:00