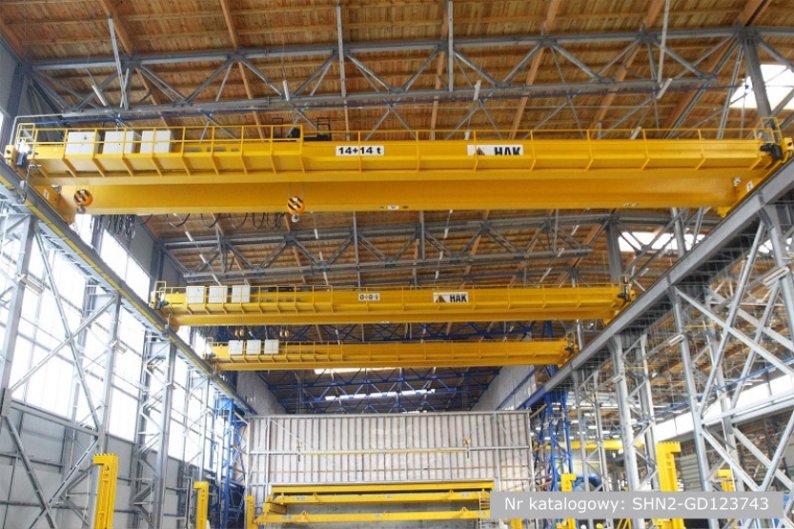

Double-Girder Crane with Magnetic Grab

Double-girder overhead cranes are versatile and widely used across various industries. They are designed for both production halls and warehouses and can also be utilized in open areas of industrial facilities.

The primary component of a double-girder overhead crane is a bridge made of two parallel girders supported by end carriages. The end carriages are equipped with a running gear for moving the crane along the track. The track for these cranes is installed on a specially adapted structure with sufficient strength. Multiple cranes of this type, equipped with collision avoidance systems, can move along a single track.

What Type of Double-Girder Crane Does Your Company Need?

Your company needs a double-girder crane tailored to the specific requirements of your operations. As a leader in crane manufacturing, we can provide this—use our offer, and we will prepare equipment with precisely defined parameters.

How Do Our Double-Girder Cranes Work?

Double-girder overhead cranes are close-proximity transport devices in the form of a double-girder bridge supported by end carriages. They are equipped with a running gear that enables them to move along the track.

What Sets Our Double-Girder Cranes Apart?

Primarily, the ease of operation. The hoists responsible for transporting goods are controlled wirelessly—easily and intuitively.

What Can We Do for You as a Manufacturer of Overhead Cranes?

Whether a double-girder overhead crane will meet your production needs depends on its parameters. However, standard models may not always meet your company's requirements.

We have a solution! By fully controlling the production process at every stage, we can prepare a crane with the specifications you choose. You will decide on:

- Maximum load capacity

- Hoist travel speed

- Hoist lifting height

- Span

- Duty cycle (group of mechanisms)

What Benefits Will Your Company Gain from a Custom-Designed Double-Girder Crane?

Double-girder overhead cranes have a wide range of applications—our clients use them in warehouses, loading facilities, and production halls. They are effective in both light and heavy industries. As one of the most popular close-proximity transport devices, they enhance work efficiency and allow automation, ensuring safety during internal transport—without using floor space.

By customizing the crane parameters to meet client needs, your company can also benefit from all these advantages. A crane made in our own production facility will be ready to handle loads of a specified weight. Such equipment will fit perfectly into your warehouse, workshop, or production hall and will help increase process efficiency from day one.

Gain a competitive edge by working with us—leaders in custom equipment manufacturing. Contact us via the form on the website, and we will get back to you to discuss the details!

Along with overhead cranes, we provide comprehensive power systems and crane accessories such as grabs, buckets, spreaders, and lifting attachments. In addition to installation and commissioning, we also organize crane acceptance by UDT and provide training for operating the equipment. In our company, price goes hand in hand with quality. All our projects are supported by warranty and post-warranty support, and we also offer service for overhead cranes from various manufacturers.