Cranes for alternative fuel storage

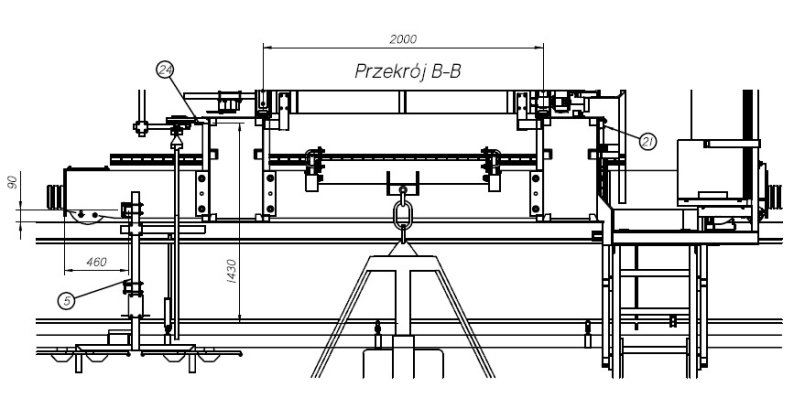

Cranes designed to support the technological process in alternative fuel storage facilities. Each crane is equipped with a wire rope hoist and a double-bucket grab for handling the load. Crane operation (movement along the track and grab handling) is fully automated and remotely controlled by the operator.

Application:

- Spreading of alternative fuel in storage, homogenization (even mixing), and loading onto feeders

- Bulk material handling processes in industries such as mining, energy, grain, as well as waste and aggregate homogenization.