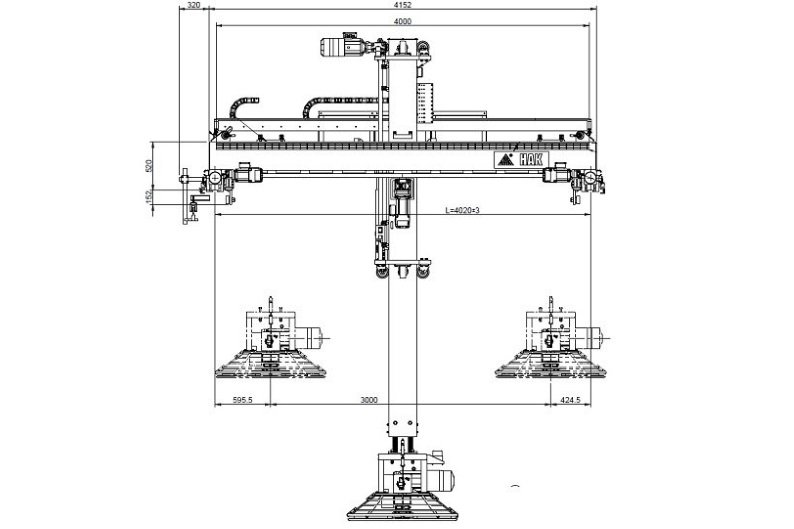

Concrete Mass Finishing Device

This solution is designed for use in the technological process at a concrete prefabrication plant. It is used for the production of concrete slabs. The special design with a crane ensures the perfect smoothing of the prefab surface.

Applications:

- In the production of concrete prefabricates with the task of finishing concrete mass.

- In processing dense masses requiring hardening through finishing.

Technical Description:

- The solution is based on a combination of a column crane working on a dedicated support structure and mechanisms used in paddle-type finishing machines.

- Prefabricates are placed on a service table located under the structure—mechanism allows for finishing concrete over an area of approx. 25 m² (1500 x 17,000 mm).

- Free operation of the mechanism by setting a cycle in automatic mode or using a remote control with joysticks.

- Collision protection is provided by signaling when the column reaches the parking position at any point on the track.

- Precise operation thanks to a data exchange system based on transmitters and sensors.

- Compact system design maximizes installation space utilization.

- Customizable system configurations are available.

The parameters provided can be adjusted to meet the user's specific needs.